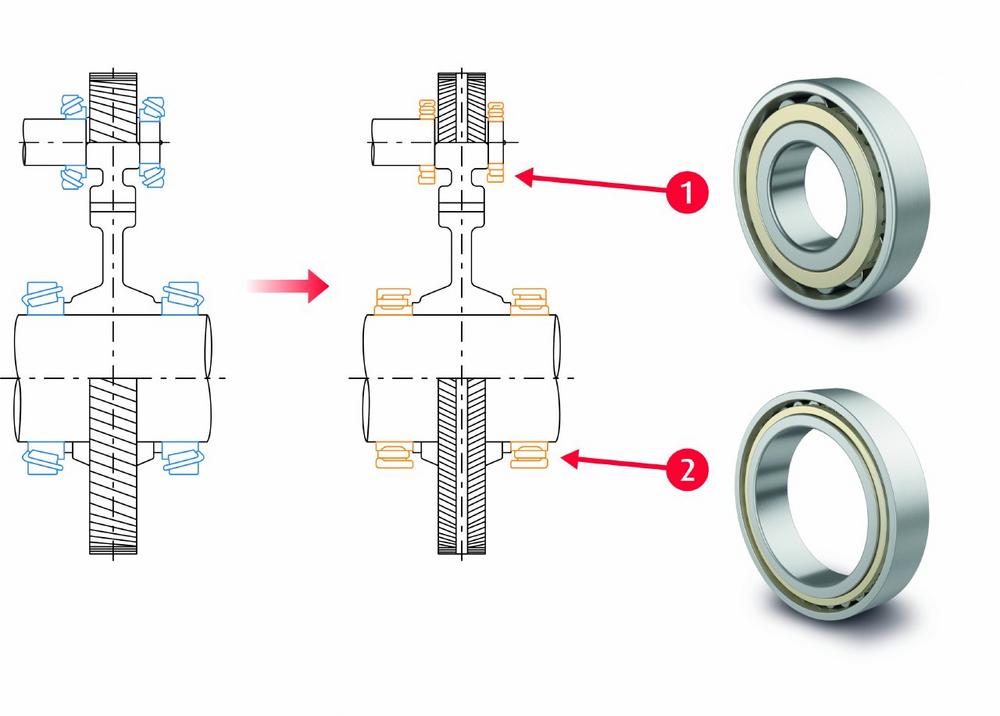

NSK, a global supplier of motion and control solutions for industrial markets, has created a new white paper about the added value that can be provided by partnering with a proven specialist in aftermarket parts. This insightful and free-to-download white paper sets out the benefits of developing a strong supplier relationship, the competitive advantages it […]

Read More