The Art of Online Surface Roughness Measurement: The New EMG SORM®

Breaking News:

Kathmandu Nepal

Samstag, Mai 25, 2024

EMG SORM® is a non-contact, online surface roughness measurement system that can be used on metallic and many non-metallic surfaces at strip speeds of up to 350 m/min. Surface roughness data is stored, displayed to the operator and, if required, fed into a higher-level network. The operator is alerted if preset limits are exceeded or if changes within the line threaten the production process.

EMG SORM® calculates the roughness parameters defined in accordance to DIN EN 10049 and SEP 1941, including the arithmetic centre roughness value Ra, the peak value RPc and the waviness value Wsa. The maximum line speed for Ra and Wsa measurement is 350 m/min and 120 m/min for Rpc.

Technological Foundation

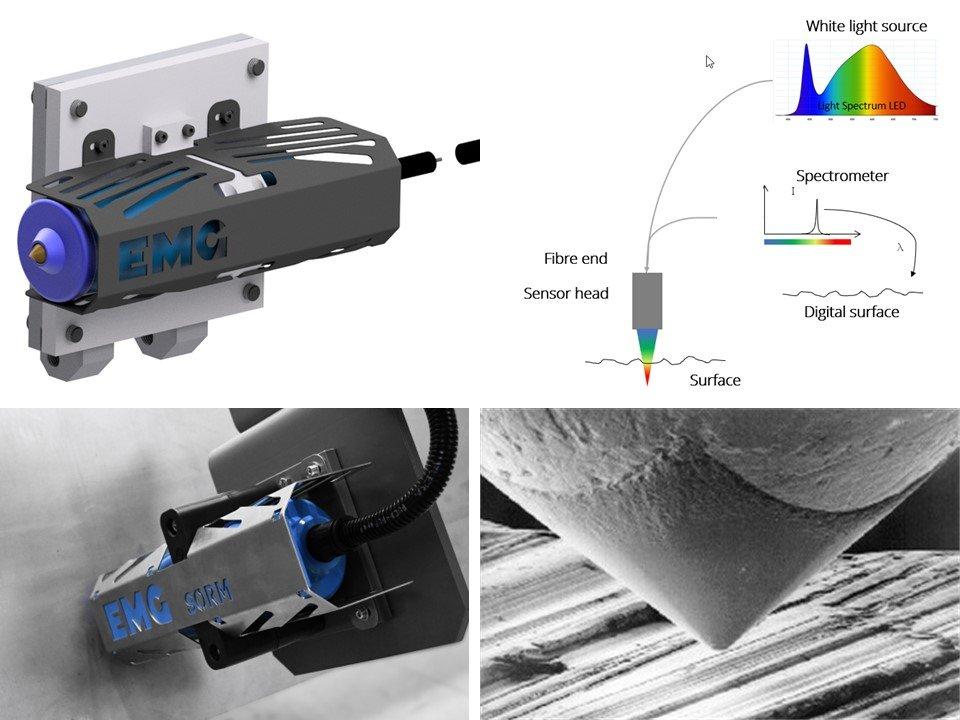

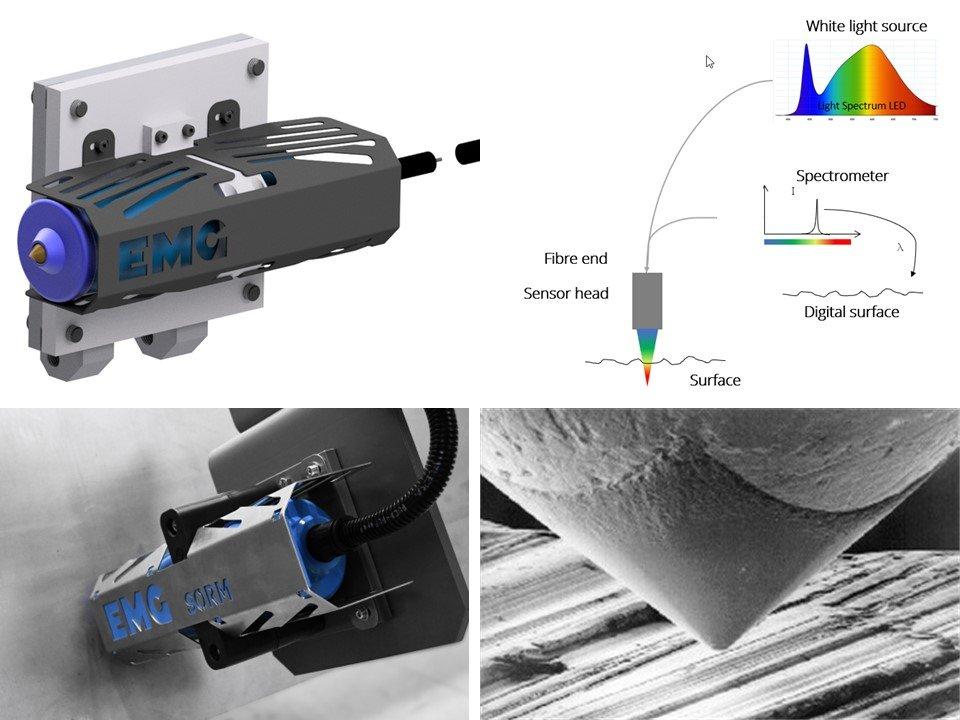

EMG SORM® relies on the confocal chromatic measuring principle, leveraging the fact that lenses have different focal points for various wavelengths of light. This unique lens property facilitates extremely accurate, swift, and non-contact measurement of distances. It incorporates different light sources (halogen or LED) within the VIS range (visible spectrum), a technology that’s already a mainstay in laboratory roughness measurement.

Key advantages

The innovative EMG SORM® offers several benefits, including improved product quality, cost reduction by optimising skin pass roll life, cost savings compared to manual stylus-based measurement, and reduction in complaints due to the early detection of deviations from the required roughness range. It also allows to reduce scrap during subsequent rework at an inspection line, to control and optimise the skin pass or rolling process, to ensure stable forming (pressing, deep drawing) due to constant roughness parameters, and to guarantee excellent coating results owing to a homogenous surface roughness.

The system provides reliable roughness data over the strip length and width and can be used for all different surface structures (EBT, EDT, LBT, SBT, PRETEX®, …) without any special adaptation. In addition, the system has a very small footprint (less than 400 mm, in production direction), which makes it very easy and quick to integrate into the line.

Summary

The new generation EMG SORM® takes online roughness measurement to a new level by combining simplicity, accuracy and speed. It integrates sophisticated technology to provide real-time data, enabling immediate corrective action in the production process. In addition to improving production quality, the system offers significant cost savings and process optimisation, setting a new standard in the industry. With its high accuracy and wide range of applications, EMG SORM® is more than just a measuring system; it’s a tool for quality assurance and process improvement.

More at: https://www.emg.elexis.group/en/metal/quality-assurance-systems/emg-sormr

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

![]()