Advanced Features for Even More Precise Drivetrain Calculation

Kathmandu Nepal

Dienstag, März 3, 2026

Furthermore, the STEP import for shaft geometries has been enhanced. A defeaturing option allows elements such as chamfers, radii, or holes to be removed. The bearing databases from SKF and NSK, along with the corresponding catalog data, have also been updated.

At the system level, multiple load cases can now be defined and flexibly selected for calculations.

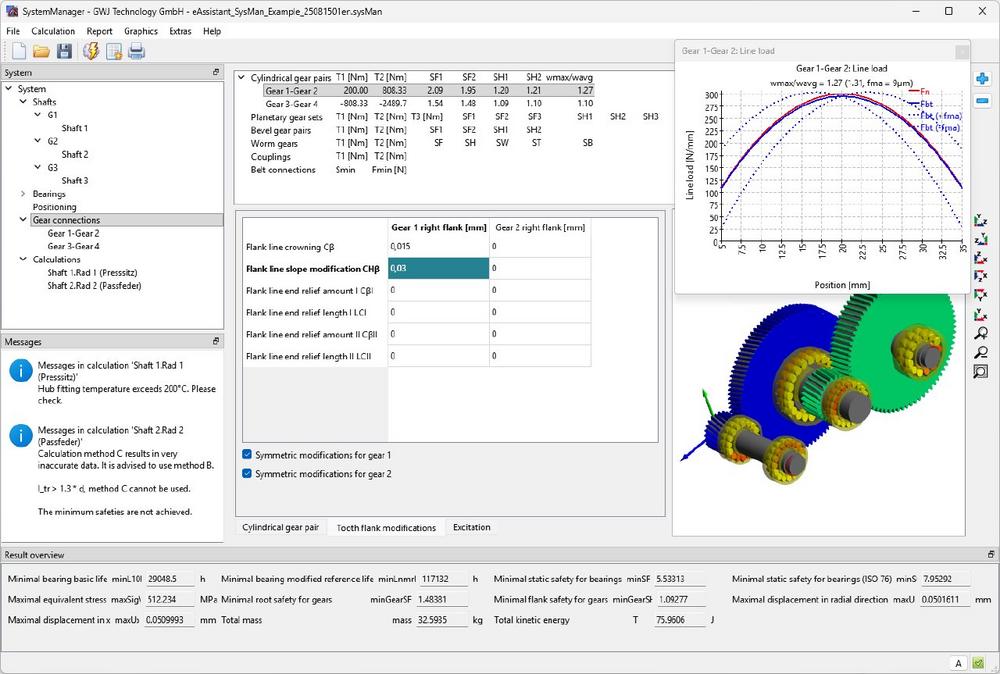

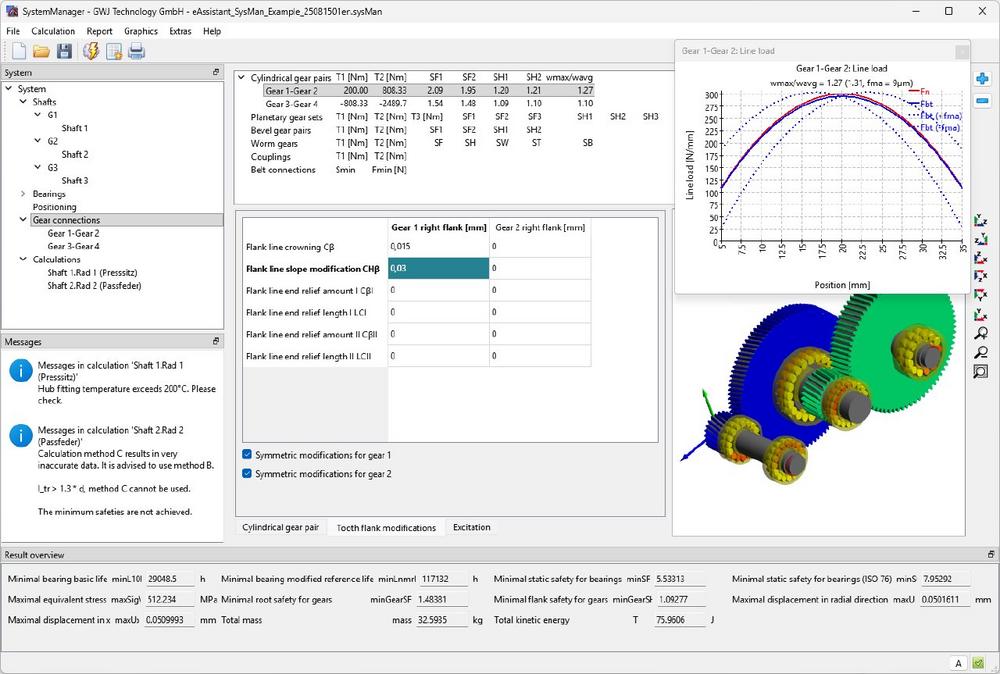

The calculation of the line load distribution for gears has also been further developed. A supplementary flank line deviation (fma) can now be specified for the gear connection. This allows alignment errors, such as manufacturing-induced flank line deviations of the gears or parallelism errors of the shafts, to be taken into account. The line load calculation is then performed with the additional fma, where only the tooth engagement stiffness at constant gear tilt angles is considered. This is then incorporated into the load-bearing capacity calculation according to ISO 6336 Method B via the face load factor.

The representation of shaft stiffness through wheel bodies has also been significantly improved. Instead of the previous two options, there are now five possibilities available, including the use of a 3D FEM mesh to account for wheel body stiffness. Additionally, rotationally symmetric wheel body geometries can now be defined directly at the force element, while complex geometries can still be represented via 3D elastic components.

In the area of visualization, users benefit from expanded sectional views. In addition to quarter-section views, a 180° section is now available. Imported housings can be displayed with custom section directions, and 3D elastic components are also shown in the 2D views.

With these enhancements, GWJ Technology emphasizes its commitment to providing engineers and technicians worldwide with powerful tools for seamless and precise drivetrain calculations. The new version of the SystemManager enables the modeling of even more complex relationships in a realistic manner, significantly optimizing system design.

Visit www.gwj.de to learn more or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date.

Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

![]()