Robotic Tread Booking: SYSTRAPLAN Boosts Quality and Efficiency in Tyre Manufacturing

Breaking News:

Kathmandu Nepal

Dienstag, Aug. 26, 2025

The escalating demands for faster extrusion speeds and accuracy in tyre tread production have rendered traditional manual loading methods increasingly obsolete.

SYSTRAPLAN’s automatic tread booking systems have been instrumental in addressing these challenges, but their latest robotic implementations are proving to be a game-changer.

High Product Quality Through Precision Handling

At the core of SYSTRAPLAN’s success is the unwavering commitment to product quality. "Tyre quality fundamentally depends on the correct transport and storage of the initial products," states Exportmanager Hartmut Brünger from SYSTRAPLAN.

Regardless of the booker type or the need for tread flipping, the paramount factor is the accurate and uniform depositing of green treads. SYSTRAPLAN’s robotic systems excel in this area, consistently producing high-quality results.

The systems offer two advanced methods for handling tread batches: the conventional surface suction frame and the innovative belt tray. The belt tray, a proven method in automatic tread booking for years, provides a distinct advantage: "the treads always keep on lying on the belts with a tight spacing and due to their own weight; and the surface can be finely structured or freshly cemented as it is not touched," explains the expert from SYSTRAPLAN, ensuring pristine tread integrity.

The Robotic Advantage

While automatic tread booking already offers significant advantages like improved product quality, continuous production, and reduced manpower, SYSTRAPLAN’s integration of robotics elevates these benefits exponentially.

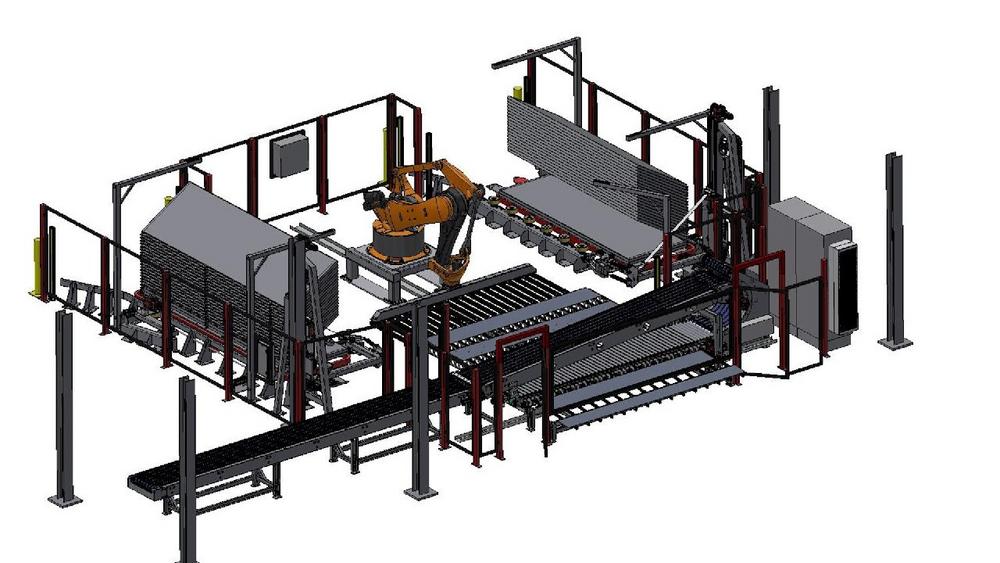

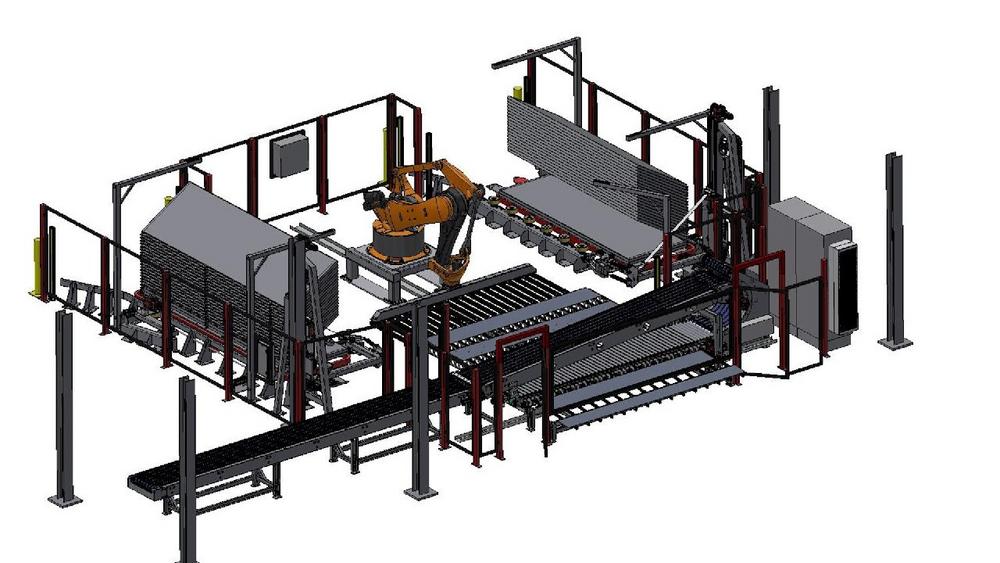

Robotic Tread Booking Systems comprise key components such as vacuum flipping, cross transfer and boomerang systems, as well as a cross conveyor for batch forming and a robot equipped with either a suction frame or a belt tray. This combination offers a suite of unparalleled benefits:

Cost-Effective Operations

Robots operate tirelessly for extended periods with minimal supervision, drastically reducing long-term labor costs.

Space-Saving Design

SYSTRAPLAN’s robotic systems are engineered for compactness and efficiency, optimizing the facility’s footprint compared to traditional automatic booking systems.

Rapid and Seamless Implementation

Robotic systems boast quicker upfront setup and require less training than complex automatic booking systems, enabling faster operational readiness and fewer interruptions.

Minimal Maintenance

Built for robustness and reliability, these robots demand less frequent maintenance, translating to reduced downtime and uninterrupted production schedules.

Sustainable and Environmentally Friendly

Robotic automation can contribute to lower energy consumption and significantly minimize material waste by eliminating human error.

SYSTRAPLAN’s commitment to innovation extends to integrating additional solutions like manual booking and work-off stations, providing comprehensive and flexible systems for diverse manufacturing needs.

With electrical control systems from industry leaders like Allen Bradley and Siemens, these robotic solutions ensure seamless integration and robust performance.

By embracing robotic tread booking, tyre manufacturers are not just streamlining their processes; they are making a strategic investment in superior product quality, enhanced operational efficiency, and a sustainable future. SYSTRAPLAN continues to lead the way, empowering the tyre industry to meet the ever-increasing demands of a competitive global market.

Customised solutions

In addition to automatic tread booking, SYSTRAPLAN also offers concepts for unloading from leaf trucks, as well as handling, storing and sorting green and finished tyres.

SYSTRAPLAN’s particular strength lies in the development of customized solutions.

SYSTRAPLAN GmbH & Co. KG

Einsteinstraße 5

32052 Herford

Telefon: +49 (5221) 7677-0

Telefax: +49 (5221) 7677-77

http://www.systraplan.de

![]()