Thermographic Fault Isolation on Chips and Power Modules

Breaking News:

Kathmandu Nepal

Donnerstag, Feb. 19, 2026

The E-LIT solution employs Lock-in Thermography as its method. This involves selectively applying electrical excitation to electronic components or assemblies in order to detect and analyze local faults based on thermal anomalies. During electrical activation of components under investigation, changes in surface temperature are measured using a high-end infrared camera from the ImageIR® series to identify so-called "hot spots”. This allows even the smallest defects, such as point and line short circuits, oxidation, and faults in transistors and diodes within circuits, which cause only minimal temperature deviations in the millikelvin (mK) or microkelvin (μK) range, to be detected.

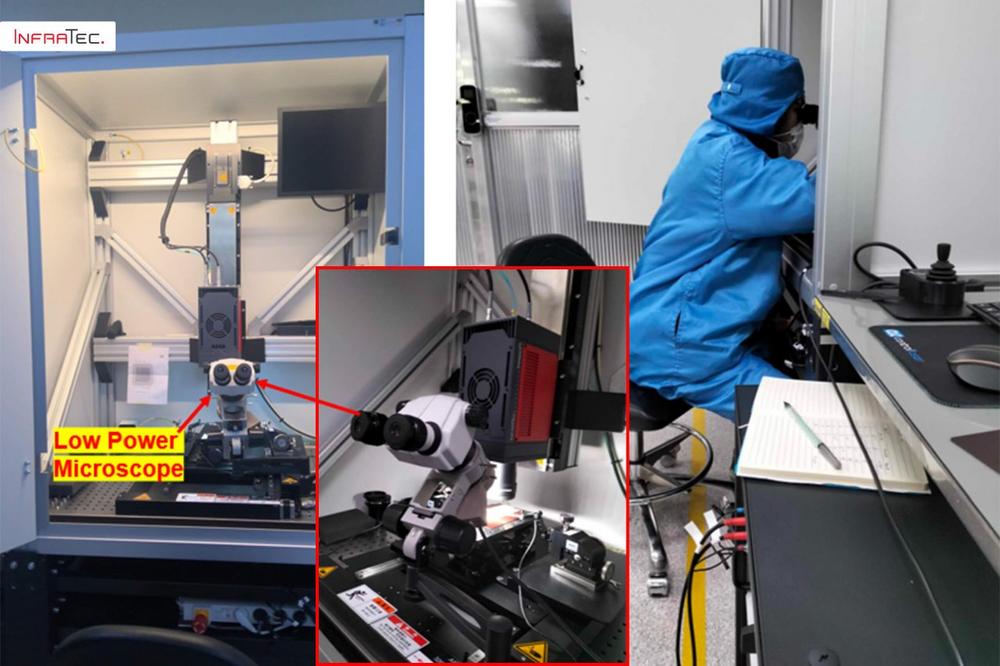

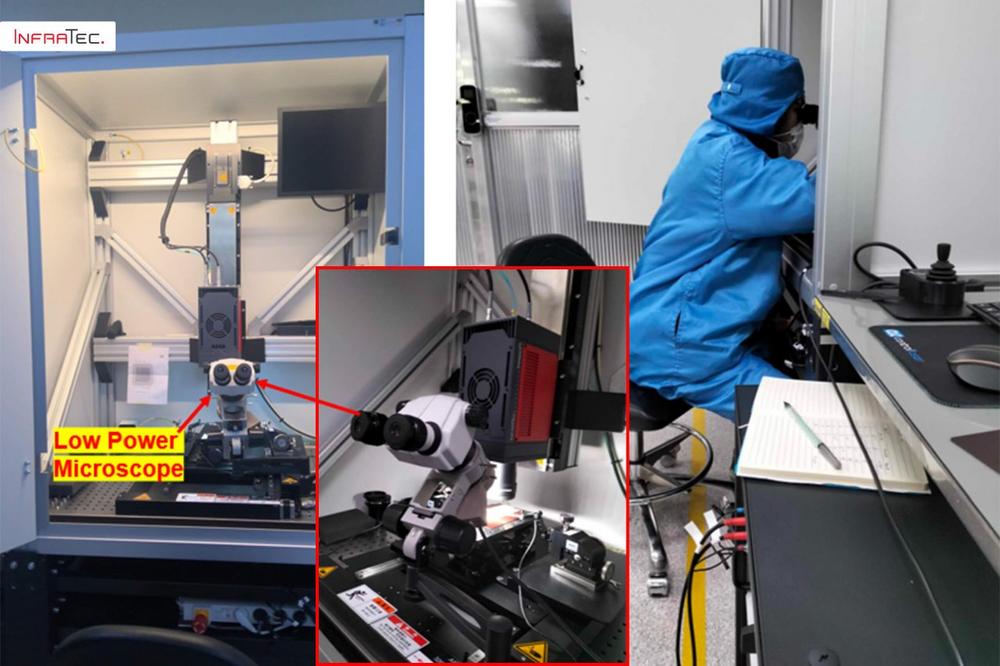

At STMicroelectronics, the test system – comprising an excitation source, an infrared camera with adjustable Z-axis positioning and additional accessories – was integrated into the failure analysis laboratory. For the analysis of large components, the E-LIT system is equipped with 25 mm lenses that provide a wide field of view, along with several microscope lenses capable of resolving fine details up to 1.3 µm. Hot spots can be detected with high sensitivity at chip level using as little as 2 μA. To excite power modules, high voltages up to 3 kV are applied.

The analysis is performed using InfraTec’s IRBIS® 3 active online operating software, which offers a wide range of comprehensive analysis functions. The use of various color palettes, including inverted and weighted modes, has proven particularly effective for fault detection.

Lock-in Thermography is a key method at STMicroelectronics for identifying faults in electrical components. The user-friendly method is especially effective in exactly locating short circuits and other anomalies. Users particularly appreciate the simple visual identification of faults and the flexibility of the system for measurements on different components such as ICs, sensors, LEDs or power modules. The E-LIT solution played a crucial role in the approval of a new mass production project in Calamba, where it was used to quickly pinpoint hot spot locations across multiple batches.

The InfraTec infrared sensor and measurement technology company was founded in 1991 and has its headquarters in Dresden, Germany. The privately held company employs more than 240 employees and has its own design, manufacturing and distribution capabilities.

With its infrared measurement business unit, InfraTec is one of the leading suppliers of commercial thermal imaging technology. In addition to the high-end camera series ImageIR® and the camera series TarisIR® and VarioCAM® High Definition, InfraTec offers turnkey thermographic automation solutions e. g. for industry processes, non-destructive testing and fire detection and prevention.

The infrared sensor division produces custom-made components – especially pyroelectrical infrared detectors – for clients worldwide. The product range includes analogue single and multi-channel detectors as well as digital multi-channel detectors (PyrIQ). The detectors are used, for example, in gas analysis, fire and flame sensors and spectroscopy.

InfraTec GmbH Infrarotsensorik und Messtechnik

Gostritzer Str. 61 – 63

01217 Dresden

Telefon: +49 (351) 82876-0

Telefax: +49 (351) 82876-543

http://www.infratec.de

![]()