How powerful visualization supports the Model Based Enterprise (MBE)

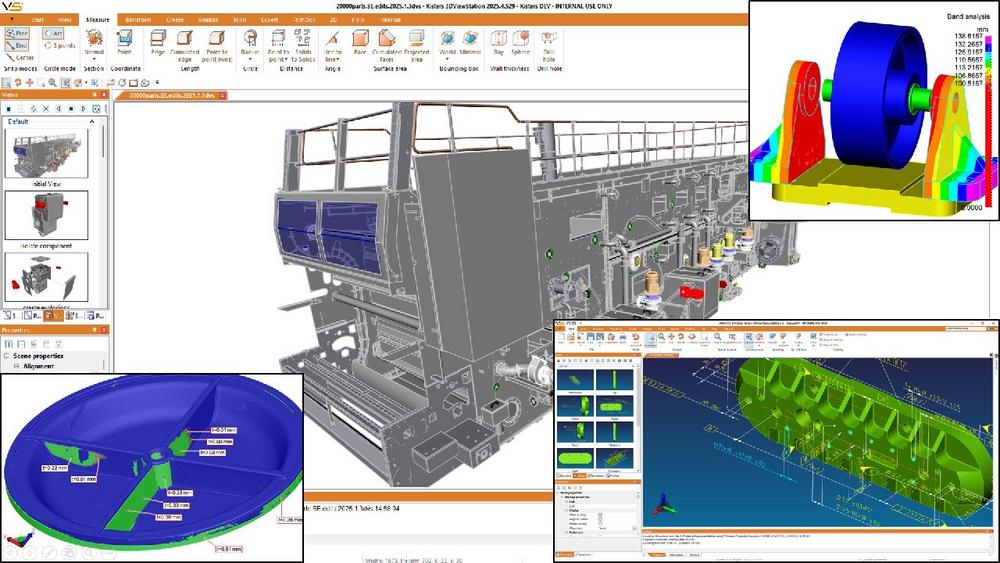

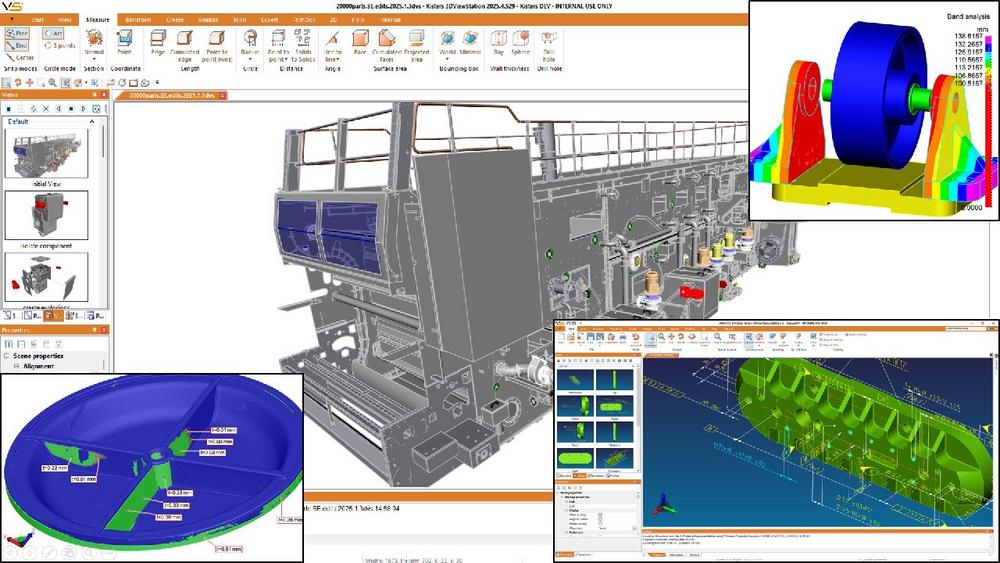

Kisters 3DViewStation is designed precisely for this purpose: as a powerful visualization tool, it supports companies in exploiting the full potential of the Model Based Enterprise. It is extremely fast, flexible, and CAD system-independent.

MBE in practice and why the 3D model is becoming the linchpin

In traditional engineering, 2D drawings contain product information such as sectional views with dimensions, surface finishes, and tolerances. This is a hindrance when this information needs to be machine-readable so that it can be processed automatically in subsequent processes such as manufacturing or quality assurance. MBE, on the other hand, takes a consistent approach: All product-related information such as dimensions, tolerances, parts lists, annotations, and metadata are contained directly in the 3D CAD model as PMIs (Product Manufacturing Information).

Kisters 3DViewStation provides exactly this access for all users in the company, from design, sales, and purchasing to manufacturing and quality assurance to after-sales and service. This makes the 3D model the central medium along the entire value chain.

“The Model Based Enterprise needs a powerful, universal visualization solution with many functionalities and PMI support. 3DViewStation ensures that information from the 3D model is available in real time to every employee, regardless of CAD licenses or CAD know-how,” explains a spokesperson for KISTERS.

Functionalities of 3DViewStation for the MBE

3DViewStation is much more than a viewer. It is an active tool for implementing the MBE approach. Key functions include:

With these functions, Kisters 3DViewStation ensures that the 3D CAD model can be used consistently as the “single source of truth” for MBE.

Enterprise-ready, as it can be used in all processes

MBE means not only a change in development, but in the entire organization. 3DViewStation can be used in a role- and process-oriented manner. Here are a few examples:

Thanks to different product variants such as desktop, WebViewer (HTML5, without local installation), VR, or embedded in company portals, your own employees as well as customers and suppliers can access identical data.

Our contribution to digital transformation

The Model Based Enterprise is a key concept for implementing the digital twin. The availability of all relevant product information in the 3D CAD model enables a consistent, error-free data chain.

Kisters 3DViewStation contributes significantly to this:

“MBE is more than a trend, it is a paradigm shift. With 3DViewStation, we ensure that companies can take this step successfully and cost-effectively,” a spokesperson continues.

About 3DViewStation

KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as a Desktop, HTML5 WebViewer and VR Edition product versions plus the online collaboration tool VisShare. All product offerings can be integrated with a PLM, ERP or other leading management system as well as service and spare part applications. KISTERS 3DViewStation provides all necessary APIs for your development team. For cloud, portal and web solutions, there is a HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address the needs of complex integration scenarios.

With more than 25 years of success in the market as a provider of superior visualization solutions from desktop to mobile, KISTERS has become the CAD viewer tool of choice within the 3D visualization industry. The company’s clients range from small firms to well-known multinationals, comprising more than 3,000 customers and over 200,000 installations worldwide. The 3DViewStation’s easy-to-use interface is suitable for all user groups and 100% customizable to everyone’s specific requirements.

KISTERS AG

Pascalstraße 8 + 10

52076 Aachen

Telefon: +49 (2408) 9385-0

Telefax: +49 (2408) 9385-555

http://www.kisters.de

![]()