Magnetic Cooling for efficient Hydrogen Liquefaction

Breaking News:

Kathmandu Nepal

Mittwoch, Sep. 3, 2025

Dr. Tino Gottschall, scientist at HZDR’s High Magnetic Field Laboratory Dresden (HLD), has long envisioned a plant capable of producing 5,000 kilograms of liquid hydrogen per day – significantly more efficient and affordable than today’s liquefaction methods. Together with MAGNOTHERM and other HyLICAL partners, his team is now working to prove that hydrogen liquefaction based on the magnetocaloric effect can be scaled for industrial deployment.

A Strategic Partnership Driving Innovation

Since 2023, HyLICAL partners HZDR and MAGNOTHERM have worked in close collaboration, combining academic expertise and entrepreneurial innovation to advance magnetocaloric cooling technologies. “Our magnetic cooling technology represents a new type of climate-friendly and energy-efficient alternative, without compressors and environmentally harmful refrigerant gases. This will enable us to significantly accelerate the necessary climate tech transformation within the refrigeration industry” says Timur Sirman, co-managing director of MAGNOTHERM, explaining the motivation behind the collaboration.

Europe’s First Hydrogen Liquefaction Demonstrator

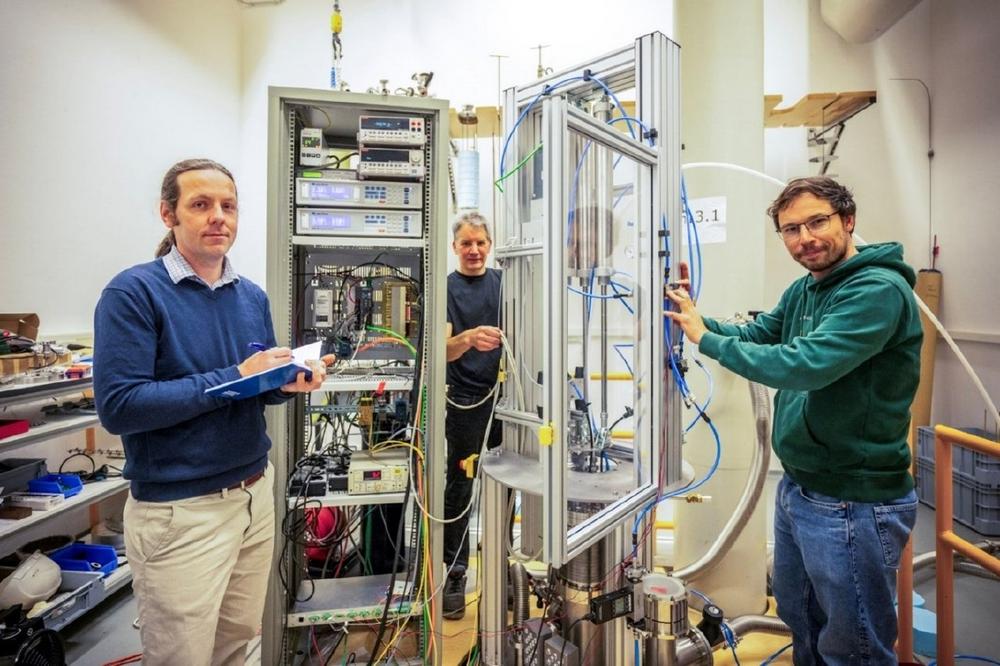

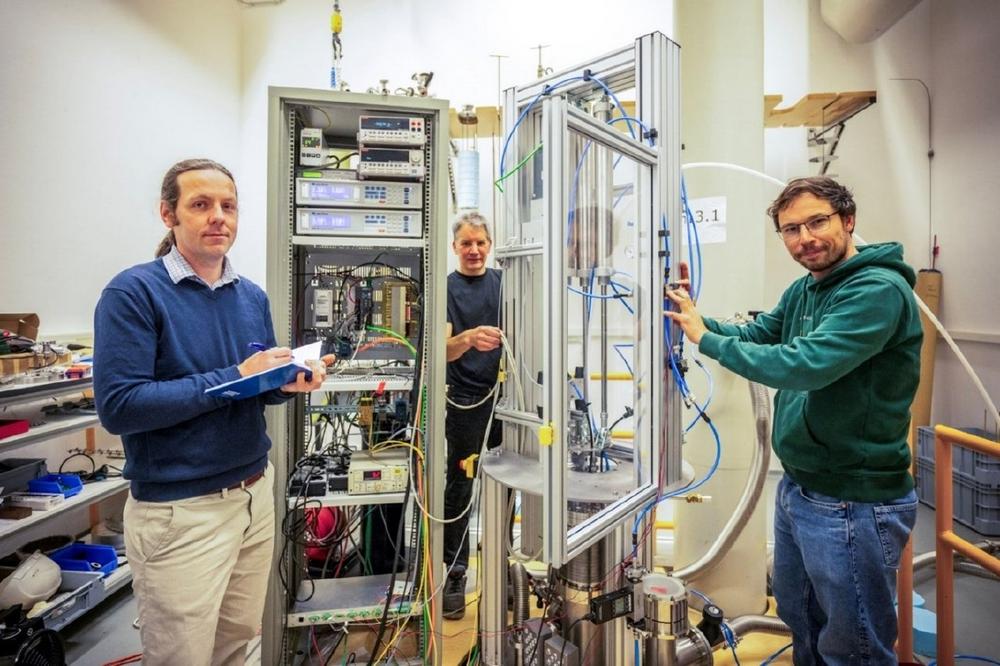

MAGNOTHERM opened a second facility on the Rossendorf campus in 2024 and established a joint laboratory in 2024, where HZDR scientist Dr. Tino Gottschall and MAGNOTHERM engineer Thomas Platte have built a pilot plant for hydrogen liquefaction. At its heart is a 19-tesla superconducting magnet embedded in the floor of the HLD. By comparison, modern MRI machines in medicine use magnets with a strength of 1.5 to 3 tesla. “We can now use this plant to prove the principle and how it works”, says Gottschall. The next target is to increase efficiency to produce 100 kilograms of liquid hydrogen per day to demonstrate the scalability of this technology for industrial deployment.

The Magnetocaloric Effect: How It Works

Europe’s first demonstrator of a magnetically cooled hydrogen liquefaction plant is based on the magnetocaloric effect. This effect occurs when materials with certain properties – one example is the lanthanum-iron-silicon alloy (LaFeSi) – are placed in a magnetic field. Depending on the orientation of the magnetic moments, the metallic materials can cause a sudden drop or rise in temperature. Using this principle, it is possible to cool hydrogen to -253 degrees Celsius after following pre-cooling with liquid nitrogen. Once this low temperature is reached, the gas begins to liquefy. “Our method offers significant advantages for hydrogen liquefaction,” notes Dr. Gottschall. “With the MAGNOTHERM joint lab at HZDR, we aim to reduce liquefaction costs to below €1.50 per kilogram of hydrogen, compared to conventional plants.”

A New Era for Hydrogen Cooling

The launch of the pilot plant is a key step in HyLICAL’s mission to advance energy-efficient, compact hydrogen liquefaction technologies based on magnetocaloric cooling. By validating this approach at pilot scale, the project supports Europe’s ambition to produce green hydrogen more cost-effectively, reduce transport costs, and accelerate the transition to a climate-neutral energy system.

About HyLICAL

HyLICAL is a Horizon Europe project that aims to demonstrate an energy-efficient, compact hydrogen liquefaction system based on the magnetocaloric effect, with efficiency gains of 30–50% compared to conventional methods. The project brings together leading European partners from academia and industry to scale up magnetocaloric hydrogen liquefaction from laboratory proof-of-concept (TRL 3) to prototype demonstration (TRL 5). HyLICAL is co-funded by the European Union and Clean Hydrogen Partnership and its members.

The Helmholtz-Zentrum Dresden-Rossendorf (HZDR) performs – as an independent German research center – research in the fields of energy, health, and matter. We focus on answering the following questions:

To help answer these research questions, HZDR operates large-scale facilities, which are also used by visiting researchers: the Ion Beam Center, the Dresden High Magnetic Field Laboratory and the ELBE Center for High-Power Radiation Sources.

HZDR is a member of the Helmholtz Association and has six sites (Dresden, Freiberg, Görlitz, Grenoble, Leipzig, Schenefeld near Hamburg) with almost 1,500 members of staff, of whom about 680 are scientists, including 200 Ph.D. candidates.

MAGNOTHERM, founded in 2019 as a spin-off from Technical University of Darmstadt, is a dynamic company with world-leading expertise in magnetic cooling and magnetocaloric materials. The international deep-tech company has channelled its intensive pioneering work in magnetocalorics into the development of magnetic refrigeration technology to market ready cooling products. The principle behind compressor-free magnetic cooling is a refrigerant-free process. The climate-tech company offers sustainable cooling solutions configured for the use in the food and retail industry, and industrial processes. Further applications, including data center cooling, air conditioning for buildings, and decentral plants for hydrogen liquefaction are already in development. www.magnotherm.com

MAGNOTHERM Solutions GmbH

Pfungstädter Str. 102

64297 Darmstadt

Telefon: +49 (6151) 7803920

http://www.magnotherm.com

![]()