eAssistant Turns 20 Years Old: Web-based Calculation of Gears, Shafts, etc.

Breaking News:

Kathmandu Nepal

Donnerstag, Mai 2, 2024

Initially active as an engineering office in the field of drive technology, GWJ participated in the distribution of a calculation software in Germany. For this GWJ already developed the first interfaces to 3D CAD systems like Solid Edge or SOLIDWORKS. Theses developments were the start of the today´s eAssistant CAD plugins which have now been around for 25 years.

Due to the practical experience gained over the years in the calculation environment of drive technology and customer suggestions, the ideas of GWJ began to develop its own calculation software, which should be more user-friendly and more practice-oriented than solutions available on the market at that time.

And then the internet took off. In order to not only implement the ideas accordingly in terms of function and usability, but also to realize a completely new business concept, GWJ invested three years in the development of the basic technology for an online working environment for the calculation of machine elements.

At the Hannover Messe in April 2003, GWJ presented the result for the first time – the web-based calculation software eAssistant. Internet access at that time came with a dial-up modem. The very positive feedback at the Hannover Messe helped to boost the new software and eAssistant with the first three calculation modules for shafts, interference fits and parallel keys was officially launched in May 2003.

The new eAssistant business model supports fast decision-making by users. All calculation modules are available automatically. The user only needs to choose between different hour packages and flat rates. As an extension, CAD integrations and the eAssistant system calculation can be added.

The fact that GWJ was a bit ahead of its time with the eAssistant at the time was shown by the necessary educational work explaning for example that users can actually calculate themselves with the web-based software, receive all results immediately at the push of a button, generate reports and open and save calculation files locally or online.

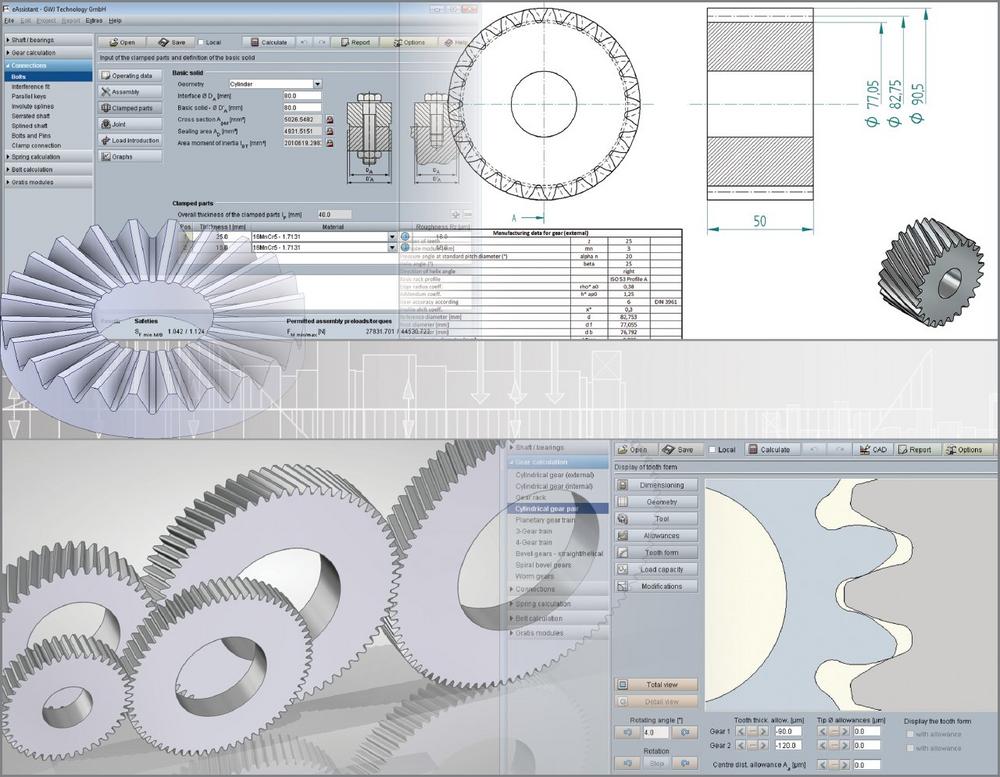

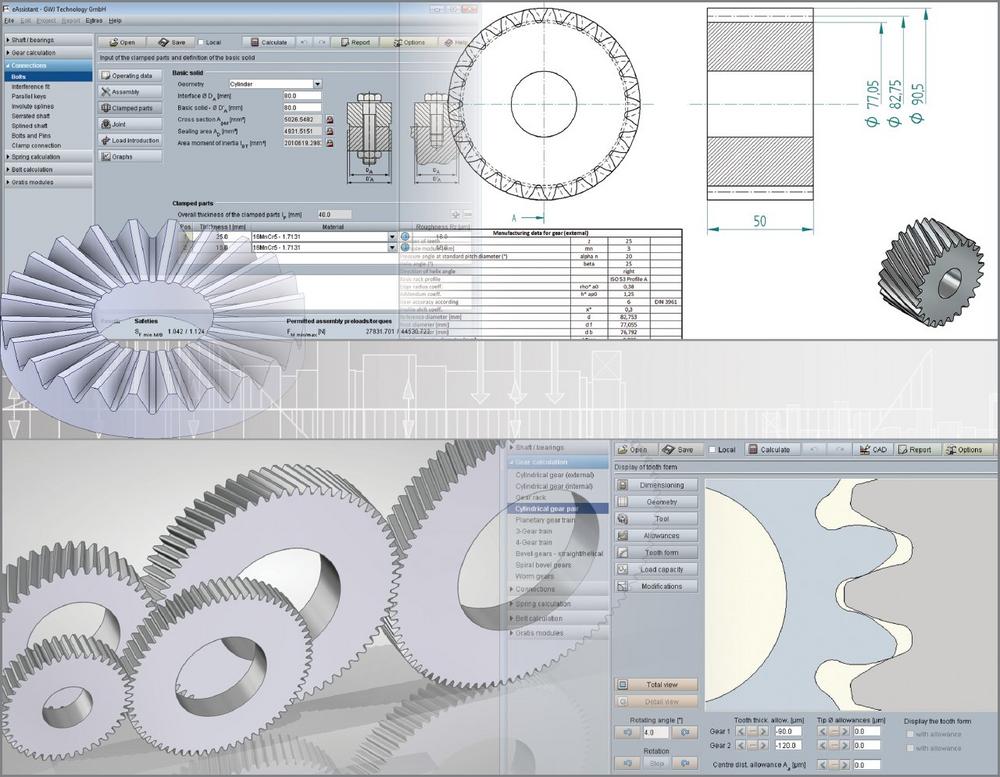

Furthermore, the eAssistant software was characterized right from the start by its redo/undo functionality and the automatic recalculation immediately after value input. The design and structure of the calculation modules are strongly based on experience from the calculation environment and user suggestions, which means that the software enjoys a very practice-oriented reputation.

In 2005, the first calculation module for cylindrical gear pairs was added to the eAssistant. This also continued the development of the eAssistant CAD plugins.

The takeover of the TBK gear calculation software, a pioneer in the field of calculation solutions for machine elements, in the same year provided an additional boost to the eAssistant development, as important calculation approaches and many practice-oriented functionalities could be taken over from TBK, especially in the gear area. In 2013/2014, eAssistant and TBK were merged into a common development platform, so that both solutions are now available with identical calculation modules and an almost identical framework. Only the business model between the online solution eAssistant and the TBK as a classic desktop solution is completely different.

With the eAssistant, GWJ Technology GmbH has meanwhile built up a very good international reputation and is today successfully represented with its software solutions in more than 45 countries on six continents. GWJ is thus one of the world’s TOP 5 software providers in the field of calculation solutions for machine elements, especially for gears and gearboxes.

Visit www.gwj.de for more information or contact GWJ at +49 (0)5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date.

Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

![]()