E.ON significantly reduces CO2 emissions at Mannstaedt by optimizing energy efficiency

Breaking News:

Kathmandu Nepal

Montag, Jun 17, 2024

Mannstaedt GmbH will be focusing on a sustainable energy concept in the coming years. The company, which is part of GMH Gruppe, has launched an extensive energy efficiency program to significantly reduce CO2 emissions. Overall, the Troisdorf-based manufacturer plans to save more than 1,800 tons of CO2 emissions per year with this package of measures. According to a calculation by the Verbraucherzentrale Nordrhein-Westfalen, this corresponds to the annual emissions of 450 to 500 gas-heated older single-family homes.

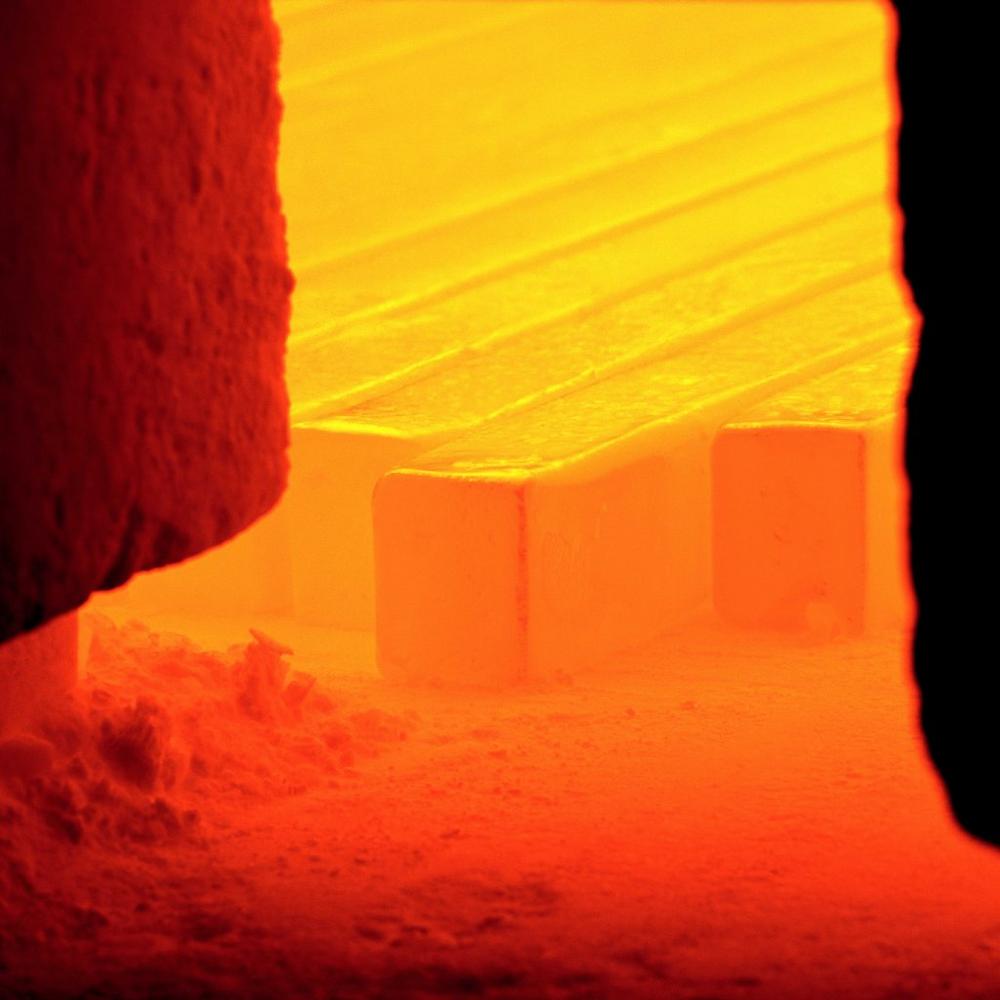

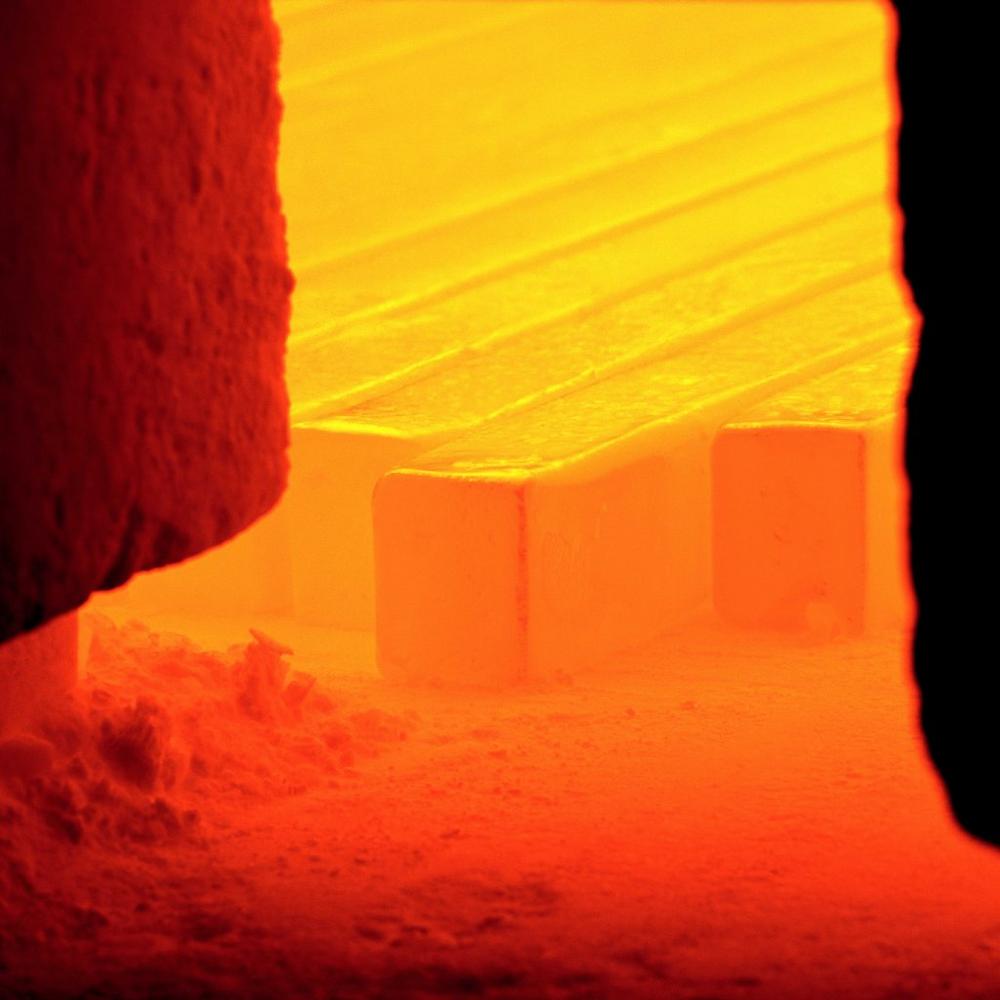

This is accompanied by savings of more than eight percent in the site’s annual natural gas usage. At the heart of this program is a heat exchanger system provided by E.ON. Hot waste gases from the production plant are fed through the new system and used to warm up water, which is then piped into the site’s heating supply circuit. Previously, this valuable energy source was released as exhaust gases into the environment via the chimney.

With this measure alone, the company plans to save almost 30 percent of its thermal energy requirements in the future. As part of the collaboration with E.ON Energy Infrastructure Solutions Germany, Mannstaedt has also initiated various optimizations at its production facilities. These projects will result in further potential thermal energy savings of up to ten percent.

“In intensive discussions with E.ON, we examined various options for a sustainable energy concept," says Sebastian Ahrens, Commercial Director and Project Manager at Mannstaedt, describing the course of the collaboration with E.ON Energy Infrastructure Solutions. "We jointly came to the conclusion that the use of waste heat offers the greatest leverage for saving CO2 emissions, also due to the performance values of our production facilities – on a scale that is not commonplace even for E.ON.”

Alexander Fenzl, Chief Sales Officer at E.ON Energy Infrastructure Solutions Germany adds: “The planning and implementation of this project is a special challenge for us due to its target values and the size of the heat exchanger system. We are proud to be able to make an important contribution to Mannstaedt’s sustainable energy concept.”

E.ON’s investment in the main plant is around three million euros. The project should be subsidized from public funds to the tune of 900,000 euros. Funding applications have already been submitted to the relevant authorities.

Mannstaedt runs the plant under a lease and operating agreement. Construction work on the new project is due to begin in the middle of next year. A particular challenge will be installing the system and all other construction measures during the vacations, in a way that avoids disrupting ongoing production. The thermal unit is scheduled to go into operation at the end of 2024. The pioneering project is one of the many transformation measures currently underway at GMH Gruppe with the aim of achieving climate-neutral production by 2039.

GMH Gruppe

GMH Gruppe offers a full-range of steel products including feed stock from melted-down scrap, through to ready-to-be-assembled components and is one of the largest privately owned metalworking companies in Europe. The group comprises of 15 medium-size production companies in the steel, forging and casting industry and is present in more than 50 countries. With around 6,000 employees, the GMH Gruppe generated annual sales of around two billion euros in 2021.

GMH Gruppe is a pioneer in sustainable steel production and has also been accepted into the “Association of Climate Protection Companies.” By recycling scrap metal, the company produces Green steel and thus makes an important contribution to the circular economy. The use of electric arc furnaces at four of its sites reduces carbon dioxide emissions by a factor of five compared with conventional blast furnaces. This, in turn, also reduces the carbon footprint of GMH’s customers.

Global customers include companies from the automotive industry, mechanical and plant engineering, railroad technology, power generation, transport logistics as well as the sectors, aerospace, agriculture and construction machinery.

The GMH Gruppe has set itself the goal of being completely climate-neutral by 2039.

Mannstaedt GmbH

Mannstaedt GmbH from Troisdorf/North Rhine-Westphalia is the world’s leading manufacturer of hot-rolled special steel profiles. The GMH Gruppe company supplies international industries with steel profiles that are individually tailored to the customer in terms of geometry and grade – from special material properties including straightness, torsion, bar or piece dimensions through to excellent surface finishes. The profiles are used in the industrial truck industry, in storage and conveyor technology, in the automotive industry and in the construction industry, among others. A large proportion of the green steel from the steelworks in Georgsmarienhütte is used as a raw material, so that the finished special profiles also have a low CO2 footprint.

E.ON is an international investor-owned energy company headquartered in Essen, Germany, which focuses on energy networks and customer solutions. As one of Europe’s largest energy companies, E.ON plays a leading role in shaping a clean, digital, decentralized world of energy. To this end, around 74,000 employees develop and sell products and solutions for private, commercial and industrial customers. More than 47 million customers purchase electricity, gas, digital products or solutions for electric mobility, energy efficiency and climate protection from E.ON. For more information, please visit www.eon.com.

E.ON SE

E.ON-Platz 1

40479 Düsseldorf

Telefon: +49 (201) 18400

Telefax: +49 (211) 4579515

http://www.eon.com/

![]()