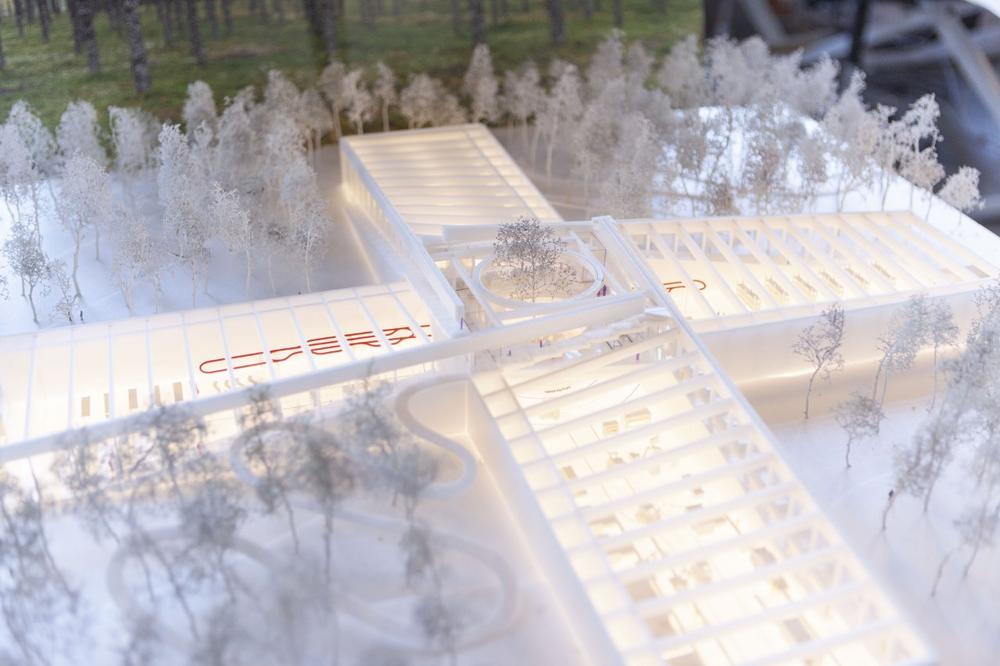

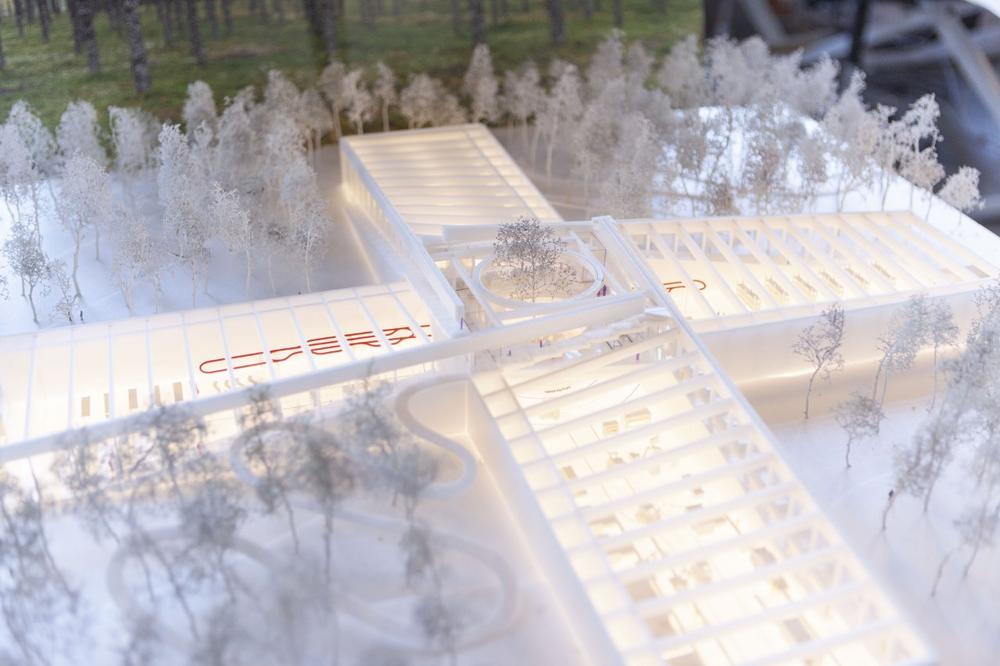

Furniture factory in the Norwegian woods

Hidden away in the middle of a pine wood, the passive-house factory in Magnor leaves the smallest possible footprint. The 4,800 m² ZinCo green roof contributes to this with biodiversity that is native to the region. It was planned and installed by the landscape gardener MATTAK AS.

888 solar modules are embedded in the green roof areas, some of which have a pitch of up to 20°, producing approx. 250,000 kWh of renewable energy each year. The Plus is an absolute plus for people and the environment and sends a positive signal across all forests of the Earth.

Vestre AS, operating worldwide, has been manufacturing urban furniture for over 75 years now and in a particularly sustainable manner. Vestre has adopted 9 of the 17 UN Sustainable Development Goals directly into their corporate policy and measures its success on the basis not only of financial results but also environmental and social results. In their search for a location for their new factory they settled on the Norwegian village of Magnor with a population of about 900. It is in the South of the province of Innlandet, 3 km from the Swedish border and 50 km as the crow flies from the Vestre location in the Swedish town of Torsby. The glass and timber industries are well established in this densely wooded location.

In direct contact with the woods

Vestre and BIG combined the wish for a building that would be economic, sustainable and social at the same time. This is when the idea was conceived of embedding the factory directly in planted pine woods and of creating an experience centre of the building and the 300 Ha of woods that would be accessible to all. Visitors can get to know all about furniture manufacturing during a guided tour, and about energy generation, recycling, water treatment or the life cycle of materials. At the same time, they experience the “woods” as a resource, and can picnic or camp there. What’s special about the overall structure of The Plus building is that you have a direct view of the production process from all angles through the enormous, glazed facades, as if they were shop windows. And, there are many points of access to this, the most open and transparent factory in the whole world. For example, two 150 m long linear staircases run in opposite directions up to the 6,350 m² large roof area. From there you can see not only into each wing of the cross-shaped factory but also into the central circular courtyard with its solitary maple tree. A circular staircase sweeps down to the courtyard. If you prefer to slide, you can take the alternative of the curved slide from the roof top right down to ground level.

As part of the further development of the area, 250 m long walkways are planned, which will weave their way upwards through the pine woods to the roof at 15 m above the forest floor. You might say that The Plus will be a viewing platform for an extended tree top walk.

Small footprint

During the construction phase, the top priority was to keep the planted pine woods as close to the building as possible. Trees were felled only where necessary, and the wood was used as construction material for The Plus. It was also vital to retain the forest soil itself as this is nothing less than a gigantic seed bank. It was carefully removed and added back later to the surrounding area and also used for the green roof. In order to intrude as little as possible in nature, the infrastructure required was installed along the existing roads, for example, for electricity, fibre optic cables, water and the sewage system.

The Plus achieved a BREEAM environmental rating of “Outstanding”, the highest possible level, which has only been achieved by one per cent of all new industrial projects worldwide. A number of elements contributed to this: the excellent thermal insulation and windows with minimum energy loss, heat exchangers and a number of geothermal wells, a forward-looking energy supply system that uses waste heat from the production, and the combination of solar energy and green roof. Overall, the energy needs of the building are 90 per cent lower than is the case with a comparable conventional factory.

Another unique feature of Vestre’s approach is that, for many years now, used and worn furniture can be brought back to the factory for restoration and reuse. The Plus has a separate circular production line for this process. This circular furniture production process reduces energy consumption considerably and even the water consumption here is minimal, given that over 90 per cent of the water used in production is recycled.

A roof with biodiversity native to the region

By lifting one corner of each wing of the building, the architects have created a special shape for the roof of The Plus. As a result, when accessing the roof, you get a glimpse into the inside of the building and at the same time a view across the building wing.

MATTAK AS, the experienced landscape gardeners, contributed significantly to the design and planning of the roof and carried out the complete installation of the green roof.

The framework structure of the roof with a pitch of between 0° and 20° consists of laminated wood beams with free spans of 24 m. Wood fibre was used for the insulation. The first layer of the ZinCo system build-up onto the root-resistant waterproof membrane is the Protection Mat SSM 45 and the drainage and water storage elements Floradrain FD 40-E. These 40 mm high Floradrain elements made from thermoformed recycled polyolefin store water in their cells and safely draw off excess water through their underlying channel system. This is the appropriate base for the vegetation required for areas with a greater variety of species. In addition, thanks to the full-cover installation, it provides the necessary position stability even in the areas of the roof with a greater pitch.

The System Filter SF was installed next as a covering, followed by about 12 to 40 cm of substrate which was lifted onto the roof by crane in turbobags. In order to plant various native species MATTAK AS created a special substrate mixture using the forest soil that had been removed. In addition to planting the seeds in the forest soil, an incredible 20,000 cuttings were planted, which had been gathered from the surrounding area and specifically cultivated for this application. By using this bio material, the vegetation on the factory roof reflects precisely the diversity of species that is typical for this region. This is the most valuable way of settling vegetation, especially given the fact that native flora is a suitable nutritional basis for the native insect world. To help establish the vegetation, MATTAK irrigated the biodiverse roof during the initial growth phase and provided care and maintenance until after the first season.

Plus Solar

Green roofs can be exceptionally well combined with solar energy systems, something the architects at BIG are more than aware of. Synergy effects are achieved, for example, where the vegetation provides for cooler surrounding temperatures resulting in increased output. In this respect, the 888 solar modules at The Plus have an additional benefit given their wooded surroundings and climatic location. In this way, 250,000 kWh of electricity per year are produced.

A number of different influencing factors are important for the expert planning of a solar energy system: Location of the building (wind zone, terrain category, exposure to the sun), shape and height of the building and the location of the solar energy system on the roof (middle of the roof, roof edge, corner). ZinCo offers a comprehensive product portfolio relating to all aspects of solar and green, designed specifically for the building-specific conditions.

Developments for the future

With the launch of The Plus on 3 June 2022, however, the project is not yet completed. Over the coming years, a 300 Ha play and picnic area, a lyrical walkway and a viewing tower, in addition to climbing structures and mega Vestre furniture are planned for the woods. A new bridge over the Vrangselva River will connect the park to the village of Magnor. Vestre is working together with the local council on the gradual development of a greater level of biodiversity in the woods, which to date could not grow wild due to forest management and deforestation.

Vestre has shown, with its overall concept, how industry, climate and nature can be successfully combined. The Plus is an inspirational and educational industrial project with genuine cross-sectoral and cross-border symbolic power – a good omen for the future, and one that is fully in line with the Vestre slogan “Everyone can save the world. A little”.

Author: Heidrun Eckert, ZinCo GmbH

Site board

Construction project:

The Plus, Gaustadvegen 140, 2240 Magnor, Norway

Client:

Vestre AS, 0271 Oslo, Norway

Construction year:

2021/2022

Roof area:

approx. 6,350 m²

Green roof build-up:

ZinCo system build-up Floradrain FD 40-E with biodiversity native to the region

Architect:

BIG Bjarke Ingels Group ApS, 2500 Copenhagen, Denmark

Design, planning and Installation of the green roof:

MATTAK AS, 5257 Kokstad, Norway

System manufacturer:

ZinCo GmbH, 72622 Nürtingen, Germany

ZinCo GmbH

Lise-Meitner-Str. 2

72622 Nürtingen

Telefon: +49 (7022) 6003-0

Telefax: +49 (7022) 6003-100

http://www.zinco-greenroof.com

![]()