Perfect paint preparation of agricultural equipment components

Breaking News:

Kathmandu Nepal

Donnerstag, Mai 2, 2024

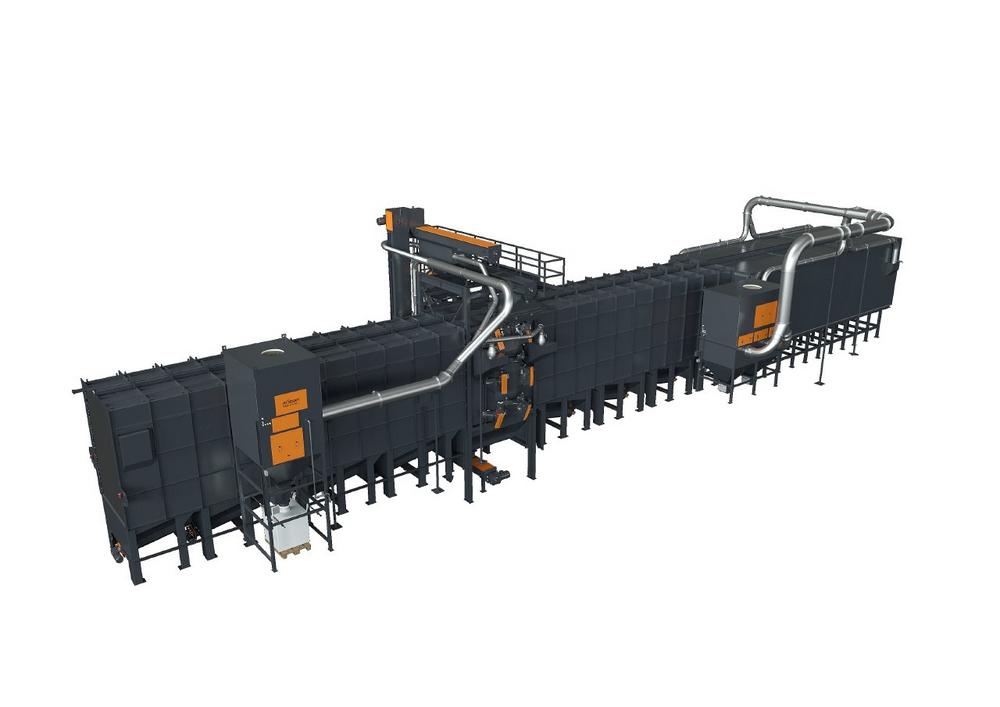

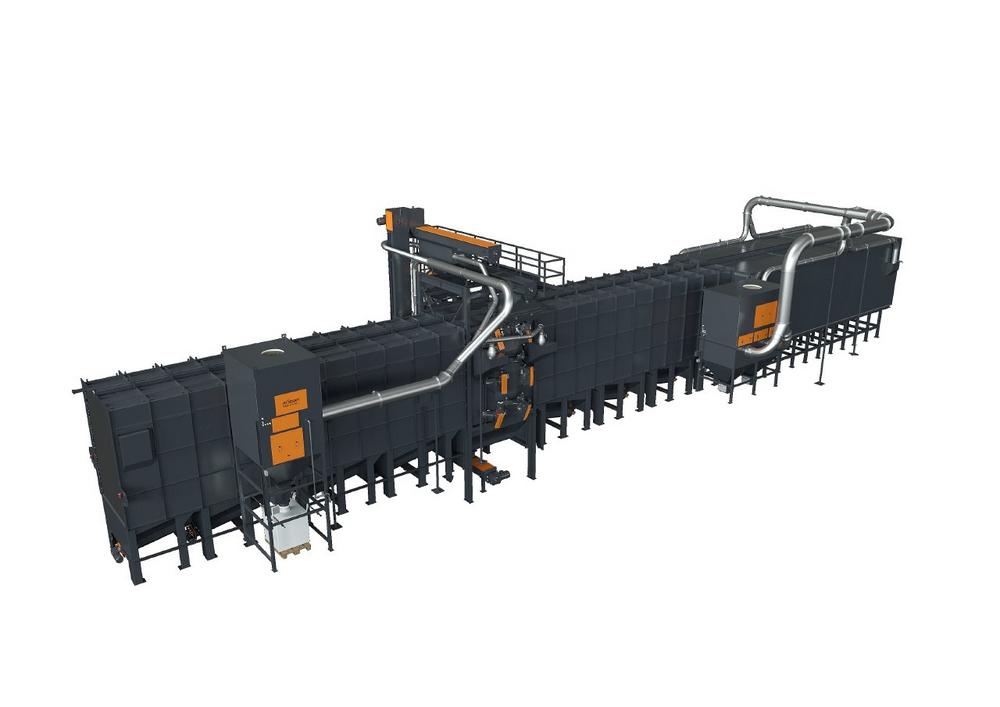

This Brazilian manufacturer supplies innovative agricultural machinery for a wide range of applications. For example, it is used for harvesting coffee beans and sugar cane as well as for seeding and cultivating all kinds of agricultural crops. The company is active in more than 100 countries. Reasons for this success are the excellent productivity and quality of the equipment as well as the continuous improvement of the manufacturing operation. It is not surprising that the new factory in Brazil is equipped with a fully automated, digitized manufacturing line. There, steel plates and profiles are cut, welded into complex constructions, shot blasted and painted in continuous flow operation. Based on the tailormade equipment concept, the technical implementation and the high equipment quality, the company had decided to purchase the continuous feed spinner hanger blast machine RHBD-K 22/27-HD made by Rösler. The work pieces are transported through the shot blast machine by the power & free conveyor system of the manufacturing line. This required optimal coordination of the various interfaces in the manufacturing line. But thanks to the help by the colleagues at Rösler Brazil the whole project went very smoothly.

Energy-saving shot blast operation integrated into the overall manufacturing process

After the welding operation the components are transported through an inlet chamber into the actual blast chamber equipped with 12 Gamma 400G turbines, each with a drive power of 11 kW. These innovative Rösler high-performance turbines contain curved throwing blades in “Y” design. Compared to conventional turbines the special blade design with optimal curvature increases the throwing speed significantly. This results not only in an up to 20 % higher blasting performance but also in significantly shorter cycle times.

Sophisticated equipment design allows more flexible shot blasting operation

Because of the enormous work piece diversity the shot blast machine was designed to handle welding assemblies with dimensions of up 10,000 x 2,000 x 2,500 mm (L x W x H) and weights of maximum 2,000 kg. Some of the weldments have thick walls and are very sturdy, whereas others have thin walls and are delicate. To account for these differences and to consistently achieve the required preparation grade of Sa 2,5 as well as the specified surface roughness values, the turbine RPM is controlled by frequency inverters. This ensures optimal paint adhesion and prevents warping of the thin-walled components. The variable turbine speed and the automatic control of the media flow allows precise adaptation of the blast-cleaning process to the different welding assemblies. Selection of the workpiece-specific shot blast programs is done at the master computer of the manufacturing line.

Behind the outlet chamber of the shot blast machine is a blast room that allows the manual touchup blasting of geometrically complex assemblies with undercuts and internal passages. Augers below the blast room floor transport the thrown blast media to the central media cleaning system. This eliminates the need for a separate media transport and cleaning system for the blast room.

Wear-resistant design ensures high equipment availability

The customer was also impressed by the wear-resistant design of the Rösler equipment. For example, the blast chamber is made from manganese steel and is protected by easily replaceable 10 mm thick wear liners, also made from manganese steel. Another plus is the fact that both sides of the throwing blades can be used, which practically doubles their usable life. The throwing blades can be replaced with a quick-change system without having to take the turbine apart.

For over 80 years the privately owned Rösler Oberflächentechnik GmbH has been actively engaged in the field of surface preparation and surface finishing. As global market leader, we offer a comprehensive portfolio of equipment, consumables and services around the mass finishing and shot blasting technologies for a wide spectrum of different industries. Our range of about 15,000 consumables, developed in Customer Experience Center and laboratories located all over the world, specifically serves our customers for resolving their individual finishing needs. Under the brand name AM Solutions, we offer numerous equipment solutions and services in the area of additive manufacturing/3D printing. Last but not least, as our central training center the Rösler Academy offers practical, hands-on seminars to subjects mass finishing and shot blasting, lean management and additive manufacturing. Besides the German manufacturing locations in Untermerzbach/Memmelsdorf and Bad Staffelstein/Hausen the Rösler group has a global network of 15 manufacturing/sales branches and 150 sales agents.

For more information please visit: www.rosler.com

Rösler Oberflächentechnik GmbH

Hausen 1

96231 Staffelstein

Telefon: +49 (9533) 924-0

Telefax: +49 (9533) 924-300

http://www.rosler.com

![]()