Better recycling of plastic packaging: New process extracts fragrances

Breaking News:

Kathmandu Nepal

Mittwoch, Juli 2, 2025

The new process is based on pressurized water extraction. It removes the tracer fragrance limonene from commercial HDPE packaging and does not require organic solvents. This reduces costs and protects the environment. In this way, the material quality of processed plastic waste can be significantly increased within one hour. The in-process analysis is based on infrared spectroscopy and mass spectrometry that provide the research team with data on the chemical composition of the samples as a function of different extraction conditions. The analytical data show that significantly less limonene is present in the samples after extraction. Furthermore, in addition to the fragrance, other impurities and short-chain HDPE are removed from the samples that were originally contained in the packaging. Based on these analyses, the Darmstadt experts determined the optimal process parameters for pressurized water extraction of fragrances from HDPE packaging. "The project results demonstrate the benefits of a systemic approach to solving current plastics technology issues with great social relevance," emphasizes Dr. Guru Geertz, who oversees the project at Fraunhofer LBF.

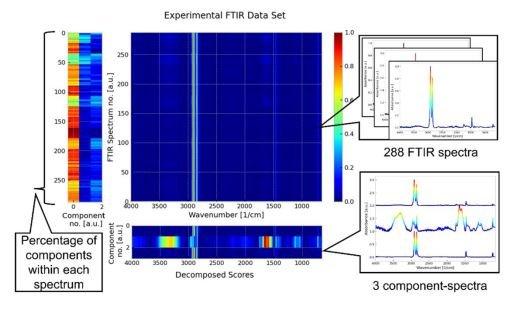

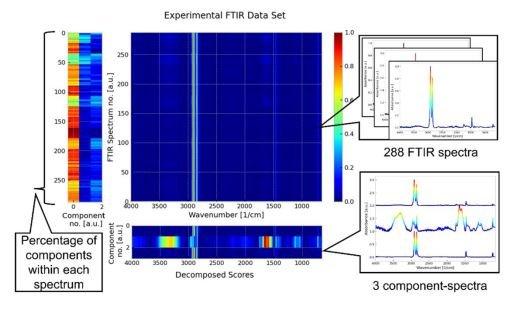

Material analysis with machine learning methods optimizes extraction process

To develop the process, detailed insights into the chemical kinetics of the extraction process were necessary, which were made possible by a novel approach for in-process analytics: Evaluating the data with the aid of machine learning methods was the key to optimize the extraction parameters in terms of the desired economical process control. At the current stage of development, an application scenario for the new process is emerging for the improved treatment of plastic waste: "The extraction process we have developed shows a way to reprocessed single-use plastics with an increased range of applications, and this serves to protect the environment," says Dr. Geertz. Due to the underlying concept, the process is equally suitable for industrialized, emerging, and developing countries, so that all market participants who bring plastic products into the trade can potentially benefit from it.

The project was funded as part of the Fraunhofer-Gesellschaft’s internal programs.

Fraunhofer Institut LBF

Bartningstr. 47

64289 Darmstadt

Telefon: +49 (6151) 705-287

http://www.fraunhofer.de

![]()