Skip grinding with MAQ STMD and Wiper edge!

Breaking News:

If Mozart were alive today, how would he feel about the Music-Domains?

Fachkräfteeinwanderung: Südwesttextil im Gespräch mit Justizministerin

Saisonbeginn am Pilatus: Es locken top Aussichten und viele Erlebnisse

Filmboard Karlsruhe wird Mitglied im Bündnis für Demokratie und Menschenrechte Karlsruhe

Kathmandu Nepal

Samstag, Mai 18, 2024

Forced to move a workpiece from a turning machine to a grinding machine to meet the requirements, grinding is expensive and time-consuming. Also, from an “energy saving” perspective, a turning operation is preferred over grinding, with its lower specific energy in machining. With a Wiper edge insert, the potential is to remove grinding post-operation and save time, money, and energy. MAQ can help you to achieve that, by taking care of the vibration with its unique STMD technology.

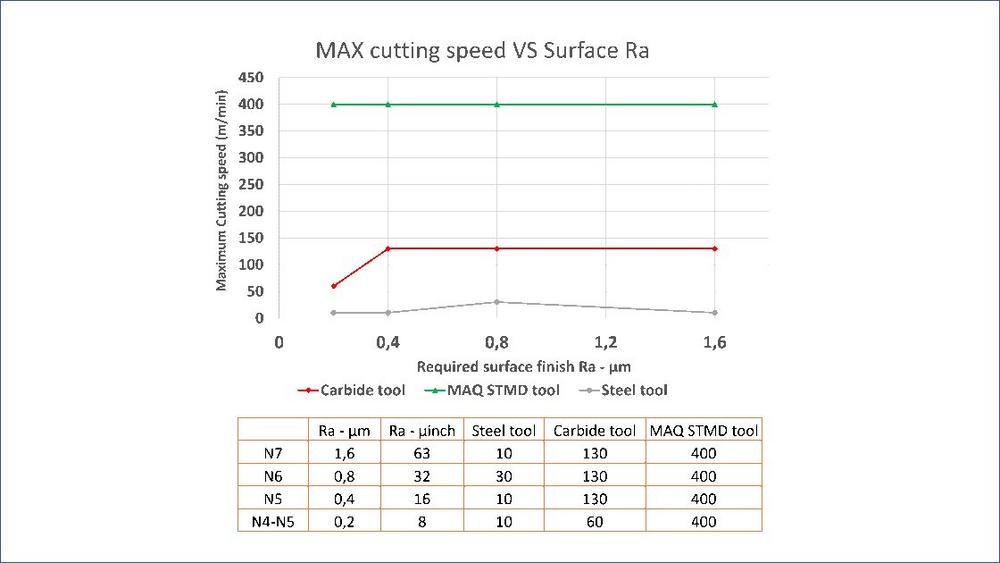

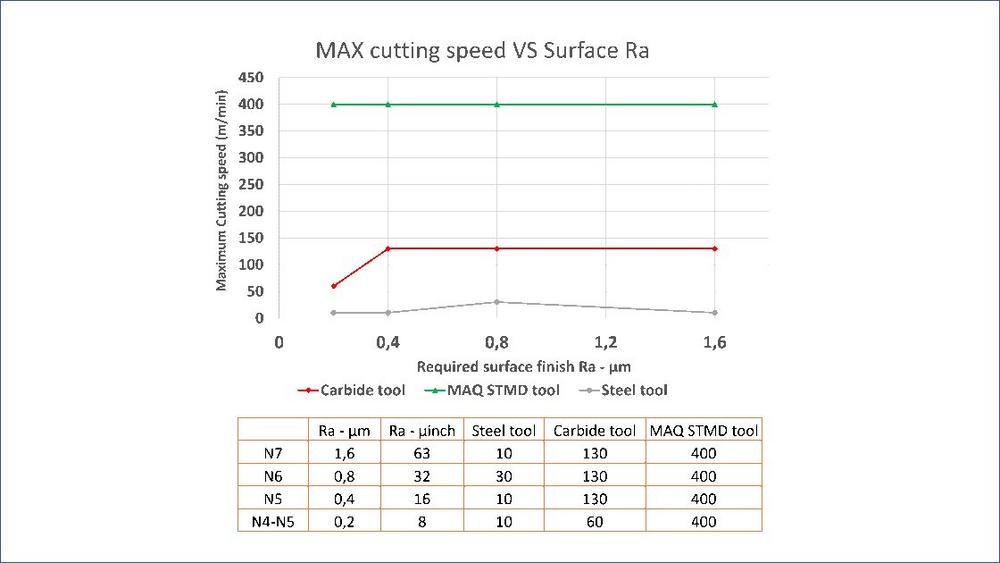

To prove what we are saying we put the different tools in the turning machine and ran the tests and below you have the results. This is a direct comparison of machining performance at 6xD setup with Wiper edge inserts, of the standard Steel tool, the Carbide tool and MAQ STMD tools. We can clearly see that it is nearly impossible to use a Steel tool holder for the test, as it vibrates constantly. A Carbide tool holder can work in some cases if we have reduced the cutting speed to 40% of the recommended speed of the insert. The problem for the Steel tool, and the Carbide tool, is the vibration. When we use a Mass-damped MAQ STMD tool we can utilize all the advantages and potential coming with a Wiper edge insert and even using the full range of feed rates.

So how challenging is the operation you have in front of you? Are we looking at a surface roughness grade (ISO 1302) of N4-N5 (Ra 0.3 µm)? If so, the MAQ STMD tool outperforms the Carbide tool with 600% higher productivity. If slightly lower requirements the MAQ STMD tools will boost your productivity by at least 200%, independent of your surface finish requirement (N4-N7).

Our mission is to bring new technology to the workshops to make things better, faster, and easier. “Simplify Machine” in other words!

Do not forget to visit our website; MAQ Web Site

MAQ AB

Stenhuggarvagen 1

S13238 Saltsjo-Boo

Telefon: +46 (70) 48697-82

Telefax: +46 (73) 20383-31

http://maqab.com

![]()