RAMPF – Material, Machine & Automation Solutions for Filter Production

Breaking News:

Kathmandu Nepal

Montag, Mai 13, 2024

Air and HEPA filters as well as oil and hydraulic filters are manufactured in a wide variety of designs and must always perfectly fit the application. Sealing foams, adhesive systems, and casting resins together with the respective processing technology are decisive both for the efficiency of the filters and the cost-effectiveness of the manufacturing process.

The international RAMPF Group offers filter manufacturers both the material – reactive resin systems made of polyurethane, epoxy, and silicone from RAMPF Polymer Solutions – and the machines for processing – mixing and dispensing technology with automation solutions from RAMPF Production Systems.

Reactive resin systems for air and HEPA filters

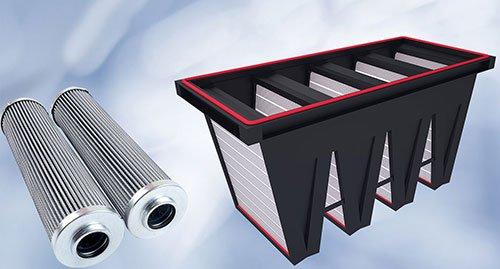

Reactive resin systems for oil and hydraulic filters

For the manufacture of oil and hydraulic filters, RAMPF has developed numerous adhesive systems and casting compounds based on polyurethane and epoxy. They exhibit good adhesion to plastic and metal as well as optimized hardening properties and fast process times, which increase the productivity and efficiency of production.

Production systems with integrated dispensing technology

With mixing and dispensing systems from RAMPF Production Systems, the reactive plastic systems used in the filter industry for bonding and sealing are reliably processed. Filters are mainly manufactured in large quantities, which requires highly automated and flexible manufacturing solutions. Here lies another core competence of the company based in Zimmer ob Rottweil – holistic automation solutions.

In addition to the core competence of mixing and dispensing technology, RAMPF provides product-specific automation concepts with integrated parts transport and heat treatment, assembly and joining technology as well as logistic and quality assurance solutions.

Alexander Huttenlocher, Director of Sales & Marketing at RAMPF Production Systems:

“The synergy effects that result from our chemical and engineering know-how in Polymer Solutions and Production Systems benefit our customers directly in form of tailor-made reactive resin systems and processing technologies.”

The international RAMPF Group stands for engineering and chemical solutions and caters to the economic and ecological needs of industry.

The family-owned company specializes in the development and manufacture of reactive resin systems, machine systems, and lightweight construction with composites.

From its origins in Grafenberg, Germany, RAMPF has cultivated a global network of partners and established production facilities in the United States, Canada, China, Japan, and Korea.

This global presence ensures a high level of flexibility in production and short delivery times – crucial success factors for our customers, who operate in the most dynamic international industries.

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

Telefax: +49 (7123) 9342-1111

http://www.rampf-group.com

![]()