Coloring high-performance plastics

Breaking News:

Kathmandu Nepal

Mittwoch, Apr 24, 2024

Due to their excellent mechanical properties and higher resistance to chemicals and/or heat, high-performance plastics also meet more demanding requirements than standard and engineering plastics. Reflecting these positive characteristics, the range of applications for high-performance thermoplastics has increased significantly in recent years: Some examples of this are to be found in the field of battery electrics.

This is becoming more and more important as a result of the growing focus on electromobility, where there are particular demands for long-lasting products with high heat resistance. Digitalization, with its increasingly powerful electronic components, also requires highly sophisticated solutions.

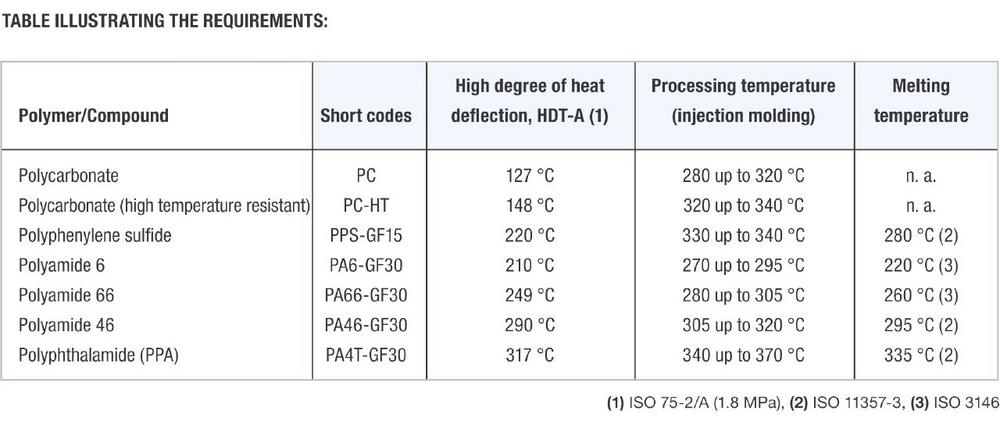

A common feature of many of the applications is that the plastics used must, firstly, meet the requirements for high thermal load-bearing capacity and, secondly, provide a wide range of colors, particularly bright colors. The reason for this is that in many cases it is necessary to have a high degree of distinguishability, for example in the case of high-voltage cables and connection components in hybrid and electric cars, which are identified in orange. In addition, a color must retain precise safety-relevant characteristics even after a long period of use or continuously high operating temperatures; for example, key markings such as those on emergency switches must not be allowed to fade.

To achieve this, colorants with particularly high temperature stability are required to ensure that the component retains its color and function even under thermal stress. To date, however, there has been very limited scope for adjusting colors for such components, as only inorganic colorants have been sufficiently temperature-stable.

The COLOR COMPETENCE CENTER at ROWA Masterbatch is able to develop the most optimal color masterbatches even for highly challenging tasks and also takes into account polymer-specific solutions for the particular component requirements of the customer. As a result, ROWA Masterbatch can also produce brilliant colors, such as RAL 1021 Colza yellow, RAL 2010 Signal orange, RAL 3000 Flame red, RAL 4006 Traffic purple, RAL 5015 Sky blue or RAL 6018 Yellow green, tailor-made for high-temperature applications in proven “ROWALID® quality”. The colorants selected are color-stable at processing temperatures up to 380 °C and exhibit very good coverage even with thin wall sections. At the same time, the resulting mechanical properties of glass-fiber-reinforced compounds are mostly retained.

The ROWA GmbH was established in 1958 and is a partner in the ROWA GROUP of companies. The brand ROWA stands for technical competence, modern product design and customer oriented service the world over. Tailored customer solutions are part of the ROWA tradition and are a matter of course! The development of new products, the search for alternative raw materials and the constant and sustained optimization of our processes, coupled with modern technology, motivated employees and economical environment protection enjoy the highest priority in our company. In 2010 the ROWA GmbH has been renamed into the ROWA GROUP Holding GmbH and the departments Lack and Masterbatch were newly formed as ROWA Lack GmbH and ROWA Masterbatch GmbH specialist division: Color and additive masterbatches.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

![]()