Simulation in child car seat design – Why do it?

Kathmandu Nepal

Mittwoch, Apr 24, 2024

Simulation offers opportunity to explore solutions to this important environment issue. Optimizing safety performance and addressing the increasing emphasis on consumer ratings as being the measure of poor, better, best, simulation presents opportunity to evaluate the design and to mitigate against poor results and the impact on sales.

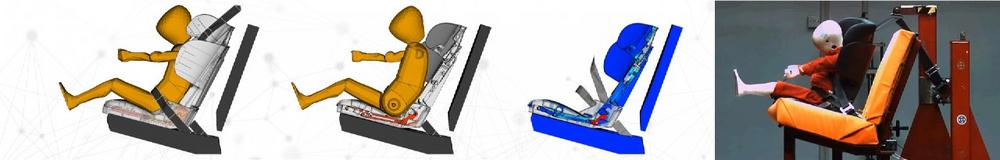

Multi award winning JMDA Design in partnership with ESI Group a global leader in Virtual Prototyping Solutions (VPS) have collaborated and served the occupant protection industry for many years. Our unique partnership has enabled many leading developers of child car seats evaluate, de-risk and build confidence in their designs at an early stage in the development.

Using VPS is a powerful tool and process is not only essential in the development of innovative and cutting edge designs, but also to control time and investment in the upstream phase of these complex development projects.

Key Topics:

Founded in 1973, ESI Group is a leading innovator in Virtual Prototyping solutions and a global enabler of industrial transformation. Thanks to the company’s unique know-how in the physics of materials, it has developed and refined its advanced simulation capabilities since its inception. Having identified gaps in the traditional approach to Product Lifecycle Management (PLM), ESI has introduced a holistic methodology centered on industrial productivity and product performance throughout its entire lifecycle, i.e., Product Performance Lifecycle™, from engineering to manufacturing and in operation. Present in more than 20 countries, and major industrial sectors, ESI employs 1200 high-level specialists. In 2019, its turnover was 146M€. ESI is headquartered in France and is listed on compartment B of Euronext Paris.

Engineering System International GmbH

Siemensstr. 12

70565 Stuttgart

Telefon: +49 (6102) 2067-0

Telefax: +49 (6102) 2067-111

http://www.esi-group.com

![]()