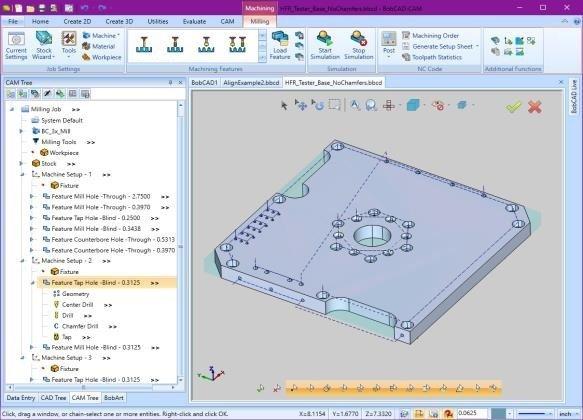

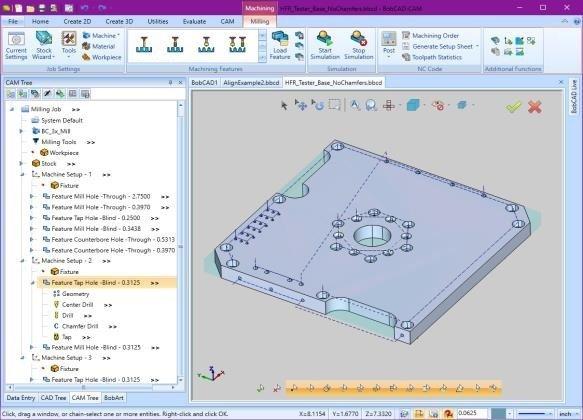

Intelligent and fast NC creation with BobCAD-CAM V33

Breaking News:

Kathmandu Nepal

Donnerstag, Mai 23, 2024

BobCAD-CAM is one of the leading CAD / CAM systems with over 150,000 licenses worldwide. You can get into CAD / CAM for less than EUR 600. The integrated 2D / 3D CAD module allows for seamless transition from part design to the advanced NC program. Effective tool path strategies support the user in creating the most complex NC programs fast and error-free.

The current version of BobCAD-CAM has 34 updates and new developments in functionality and operation.

New features of BobCAD-CAM V33

Views – The use of keyboard shortcuts in the view controls makes the software much easier to use. Views can now be rotated more easily and displayed quickly based on the current coordinate system.

Hole creation – The new function hole detection saves a lot of time through the automatic assignment of hole dimensions, including the parameters for countersinks. The correct tools and depths are automatically set using the thread information attached to the hole geometry.

Probing – BobCAD-CAM V33 offers a new probing module. Everything in the workshop is about precision. Therefore, probing is an indispensable part. The possibility to check work and tool failures with 100% accuracy, the option to check tools for breakage and to inspect finished parts can save a lot of time and money.

Barrel Mill Tool Types – BobCAD-CAM now supports Barrel Mills for most milling operations. These tools can extremely shorten the processing time when 3D models are processed by greater depth infeeds.

Tool library – The tool library of BobCAD-CAM V33 is now available in XML format, which allows to import tools from the catalogs of tool suppliers into BobCAD-CAM.

MachiningCloud – Exports from MachiningCloud tool assemblies can be transferred directly to the tool crib or the tool library. As a result, the tool geometry for collision control and simulation of the milling and turning tools is as accurate as possible.

Finishing Steep and Flat Areas – The new Machining Steep and Flat Areas operation can perform calculations 78 times faster than basic Z-plane finishing.

This is only a small selection of the new features and optimizations of BobCAD-CAM V33.

The budget-friendly and powerful modules of BobCAD-CAM

Modules for 2.5 to 5-axis milling operations, 2 1/2 D turning, complex 5-axis milling and turning operations on machining centers, as well as for laser, plasma and water cutting and wire EDM, cover the most important areas of machining . With BobCAD-CAM, the entire workflow within just one program is possible, from the construction of the part geometry, the programming of the tool paths, the simulation of the entire machining process, to the transfer of the data to the machine tool. Standard postprocessors that can be adapted to the capabilities of the machines are free for common NC controls.

BobCAD-CAM is available as a stand-alone CAD-CAM system and as an add-in for SolidWorks.

Users who only need a powerful CAD system can obtain the BobCAD-FreeCAD CAD system free of charge. If necessary, BobCAD-FreeCAD can be cost-effectively expanded into a complete, high-performance CAD / CAM system.

If you are interested in trying out BobCAD-CAM V33 you can download the program and get a trial license.

Founded in 1998, DataCAD Software & Services GmbH is a leading provider of technical software solutions for industry. The company’s goal is to provide affordable software for a wide variety of industries. Industrial sectors in focus are, for example, the automotive and aircraft industries, mold and toolmakers, general manufacturing, prototype construction, woodwork, jewelry design, arts and crafts, hobby and education.

DataCAD Software und Service GmbH

Gutlay 4

55545 Bad Kreuznach

Telefon: +49 (671) 8363-10

Telefax: +49 (671) 4820-293

http://www.datacad.de/

![]()