Forewarned is forearmed

Breaking News:

Kathmandu Nepal

Dienstag, Apr 16, 2024

Electrostatic charge, primarily caused by friction between two objects, can lead to sudden electrical discharges as well as other, mostly unwelcome effects. Such discharges can have serious consequences, in particular in explosion-proof areas, and are consequently to be avoided at all costs.

On account of their high electrical resistance, plastics are particularly influenced by electrostatic effects. They are therefore often provided with an antistatic treatment during the production process. As an alternative, plastics can also be given an antistatic finish retrospectively – for example by means of a suitable coating.

There are various methods of providing antistatic properties to lacquer systems: Conductive carbon black, graphite, graphene, quaternary ammonium compounds, modified mica, singlewall and multiwall carbon nanotubes or conductive polymers can be used in the corresponding coating formulations. All of these raw materials have their own specific advantages and, more importantly, disadvantages. For instance, quaternary ammonium compounds wash out over time and the antistatic effect deteriorates. Conductive carbon blacks and graphite produce a deep black coloration of the lacquer, modified mica demands a high load, and conductive polymers are usually extremely expensive.

The product range offered by ROWA Lack now includes various antistatic lacquers, which can be applied to meet a variety of customer requirements, for example in the field of biogas membranes.

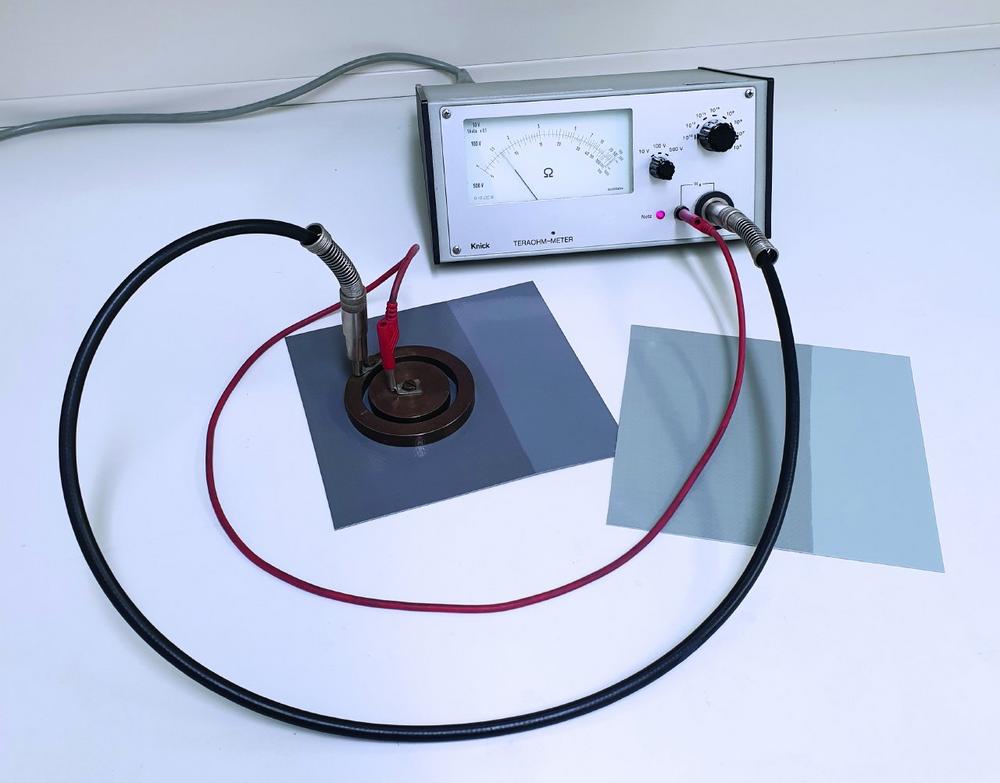

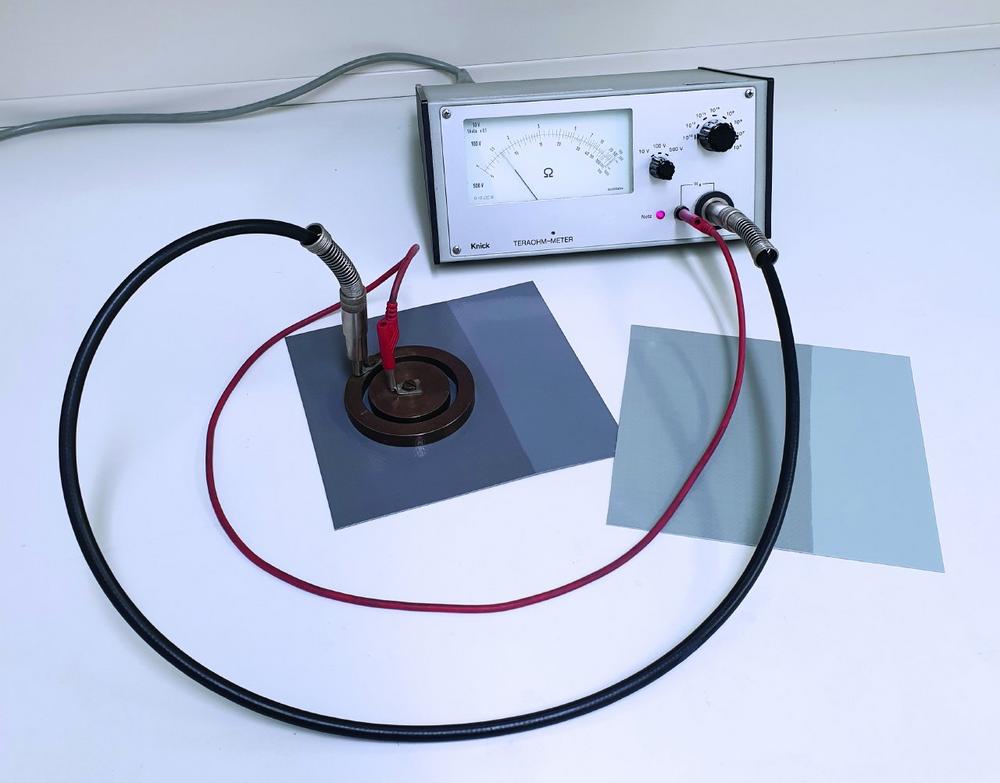

With ROWAKRYL® G-34747W, for example, it has been possible to design a high-gloss, water-based product with very good slip properties and a surface that is only slightly darker or grayer in comparison to that of conventional lacquers. Surface resistances of < 107 Ω can very easily be achieved with this lacquer. Also the welding properties of the lacquered goods are maintained by means of hot air processes.

New products ROWAKRIL® G-35198 and G-35217 are available in the solvent-based range. Once again, products with good optical and haptic properties or even good hot air weldability have been developed by a specific selection of antistatic agents.

As usual, ROWA Lack offers its customers tailor-made product solutions for special requirements, such as when a defined surface resistance is to be attained. If you require any further information please do not hesitate to contact our experts.

About the ROWA Lack:

The ROWA Lack GmbH was established in 1958 and is a partner in the ROWA GROUP of companies. The brand ROWA stands for technical competence, modern product design and customer oriented service the world over. Tailored customer solutions are part of the ROWA tradition and are a matter of course! The development of new products, the search for alternative raw materials and the constant and sustained optimization of our processes, coupled with modern technology, motivated employees and economical environment protection enjoy the highest priority in our company. In 2010 the ROWA GmbH has been renamed into the ROWA GROUP Holding GmbH and the departments Masterbatch and Lack were newly formed as ROWA Masterbatch GmbH und ROWA Lack GmbH specialist division: Special Lacquer Systems and Top Coats.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

![]()